Hello Masters of the Composite Universe:

Well, I am still learning a lot from your great forum.

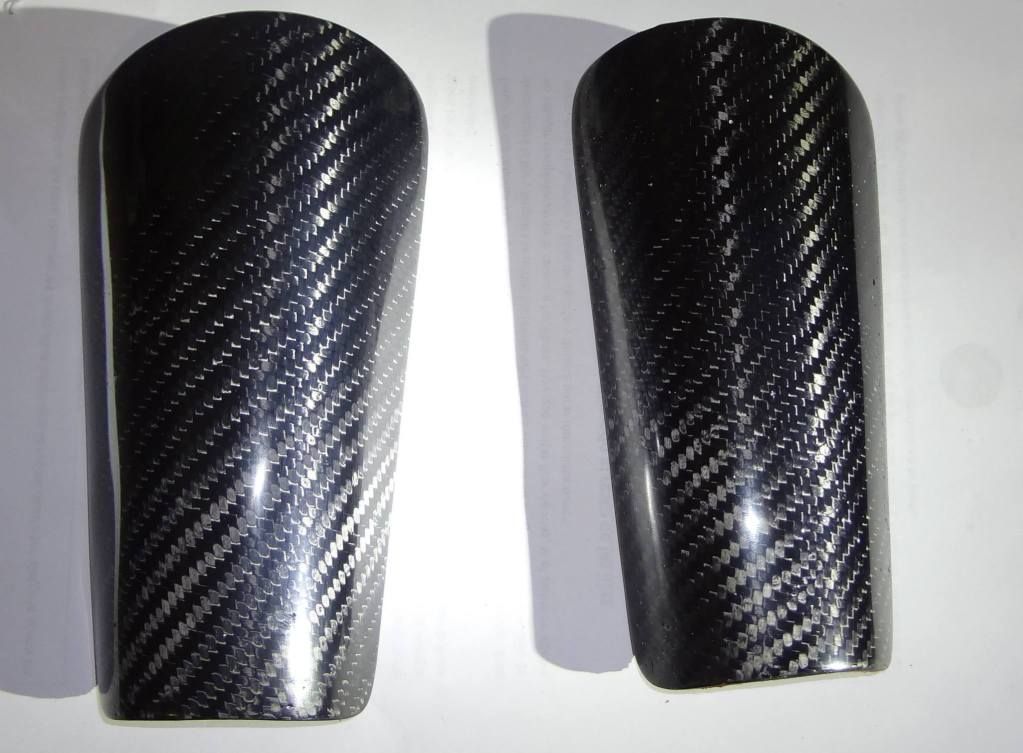

This time I have a project for my cousing, he is an amateur soccer player, and he would like to have some shin guards for him, custom made.

I am about to do the molds, there should be no major issues on this, I will take as a plug a pair of his favorite shin guars.

At this moment, I have a roll of sweet twill 2x2, 199 gsm, I am doubious about how many layers of this cf I should use.

On some products offered in the web, some fabricators mencions that they do not use any core materia, they use 100% cf. I think this is a good way to go.

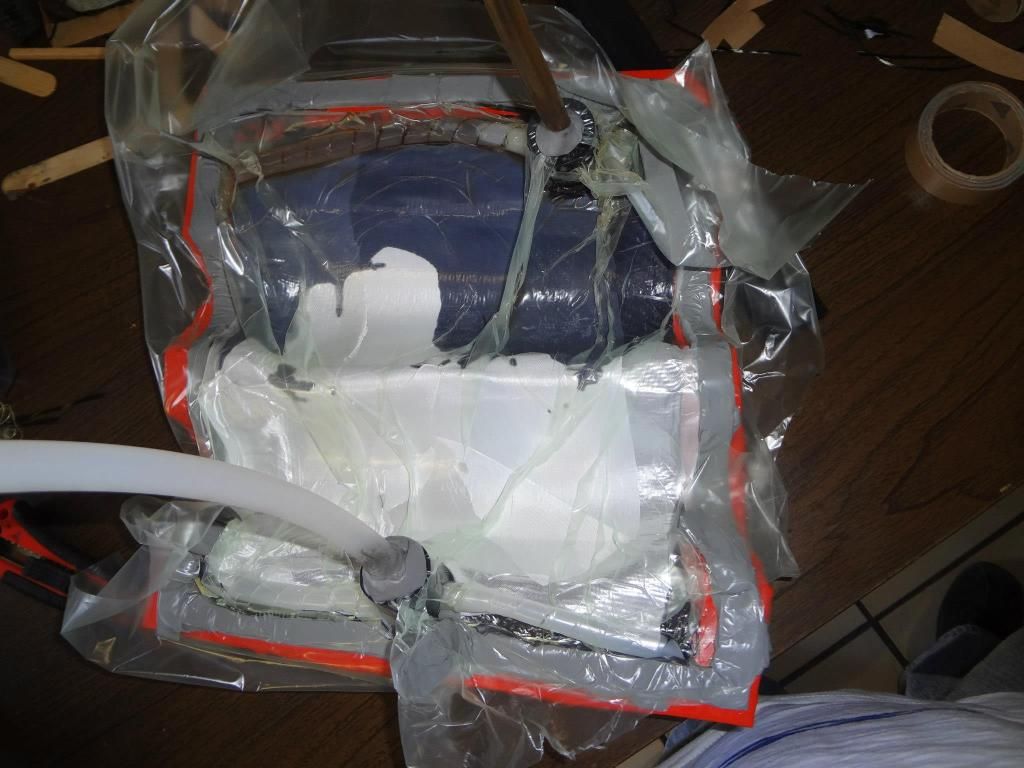

I am considering maybe to use 6 layers of the mentioned cf, not pretty sure if this will be enough, and infuse as for first trial. I have use some vinylester resin for some infusion test, which I consider strong enough for this project.

Any recomendation will be greatly welcome.

Best Regards!

Antonio