That is very interesting, because i have the same thing in my parts

What kind of resin are you using, what viscosity?

CHECK THIS out .

http://www.aitracing.com/shop/index.php?main_page=vip

Porosity is a problem, not something normal that should be expected with infusion.

I’ll see if I can get some pics of unpainted finished parts around my shop.

2supercha: Thanks for videos, I saw them several times before. I really dont know what Im doing wrong.

2TET: Please if you can post any picture of infused parts without gelcoat or any other coat.

I made a tiny infused piece between two vacuum bag foils. It was only 2 layers of carbon twill. Because of the foil from both sides, vent tube was almost closed with bag. Final piece seem to have lot of resin in, but it dont have any dry spots. Absolutely no pinholes. So my problem is really with sucking too much resin out of laminate. I will make next infusion today if I will have time.

What is your gel time for your resin? Heating it might be an issue if the manufacturer doesn’t recommend it. Also, if you can, allow the resin flow through the part for awhile and then clamp the inlet off. You don’t really want the resin in the part for hours after you clamp it off before it gels…else, yet, resin will get sucked out. These pieces were 24hr geltime, but the infusion time was 10min…lots of resin sucks out, which is normal.

Thanks for great pictues riff42.

My resin parameters:

Gel time at room temp (20-25°C) is 8-9 hours

Gel time at elevated temp (40-45°C) is 3-4 hours

Optimum processing temperature 15-40°C

Viscosity at 25°C is about 200mPas

Viscosity at 40°C is about 80mPas

I had same problems with thicker resin with 1,5 hour geltime.

Helpful hint- Provide the air an easy way to escape but tough for the resin to flow through.

Hey TET, just wondering if you have tried or are using Saertex’s VAP membrane. I just got a sample a few weeks ago, havent gotten around to testing it. I dont have the problem these guys are having but what you are describing sounds alot like this. If you have tried it what do you think of it?

Never used Saertex’s but I have used GoreTex’s membrane. Works wonders depending on what resin you use. Epoxy is good, but VER would go through it. Works well for things like powdered BMI infusions. Of course, you can’t SEE the resin fill the part, so you don’t know when to clamp the inlet

GUYS!!! I know how to get a high quality infusion

I did 2 different infusions yesterday, 2 different ways and one of them came out very well.

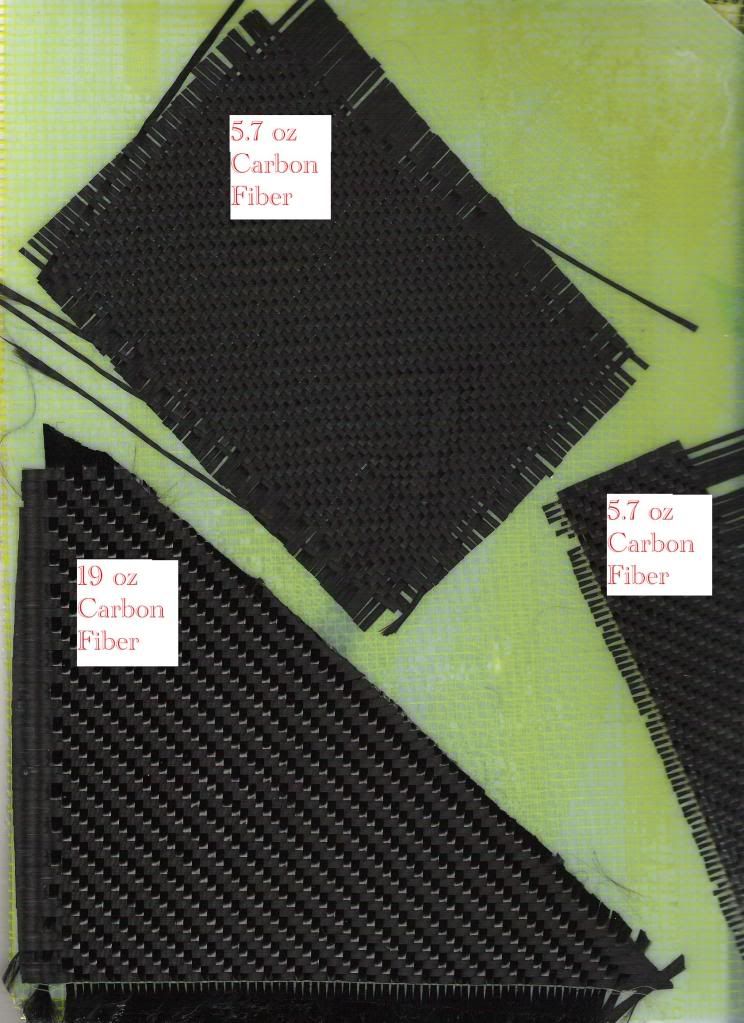

On the picture you can see 2 - 5.7oz ones and 1 layer -19 oz

The 19 oz one came out very good with out any air bubbles

The 5.7 ones are PERFECT . If you see some “PIN HOLES” , they are not pin holes, the 5.7 is so THIN

Can you repeat this on something the size of a boat? What was your solution?

I do not know about a boat size, but i am going to try to do the same thing in 50"x35" scale

Here is how i did

I was laying up on the glass

Steps:

- Waxed two times

- Applied PVA

- Sprayed Automotive CLEAR COAT and let it to full cure

- Layed my fabrics

- peel ply over the fabrics

- flow media

- Heated up the resin until 110 degree and infused it under 24-25 HG vacuum and then start hitting up the glass with the HEAT LAMP (110-130 degree hit was applied) until it gets in a gel stage

I was using a THIN CLEAR SLOW SET

The Viscosity —500 to 770 cPs Mixed at 25oC

The part came out with out any air bubbles

This is a scanned picture, but i will take some better pics

have you found the panels to be lower in air content using a membrane?

I haven’t done enough infusions with it to know. I’ve had to use it on some parts (powder infusion), and personal parts that I never did density/FVF on. But in concept, it should pull all the air out, and leave voids filled with resin…that is what the beauty is. People that have used it here, love it…but it’s another step, and expensive

Okey, problem solved. Its definitely excessive draining. My resin have very long potlife and very low viscosity so no matter what I do it always drain the laminate. So I infuse part full, resin enter the outlet (about inch), I clamp it there. First time I saw beautiful surface!!! I will test version with additional draining from feed port (after infusion and vac port clamp) for a sec and then clamp it off.

My first successful made!!! Look at ,Showcase, section. Enjoy

I am glad you worked it out but just as a short warning to others.

Most resins have a vapor pressure somewhere less than 1 torr (1000 microns in vacuum) Most resins will boil when you pull a hard vacuum and that will create bubbles in your resin. The point to pulling a vacuum with a vacuum bag setup is to use the ambient air pressure to debulk and compress your layup against the mold/mandrel and to squeeze out excess resins.

Sea level air pressure is around 14.7 pounds per square inch or 760 torr. A micron in vacuum terms is .001 torr or one thousandth of a torr. Pulling a vacuum to below 1000 microns or 1 torr will gain you a whole additional .02 pounds per square inch of pressure on your layup… and probably make your resin boil as it’s curing.

Most decent single stage vacuum pumps can get down to the 100 micron range. A good two stage pump can get to 10 microns. A pump that will pull the chrome off a trailer hitch WILL cause the resin to boil, creating bubbles. If you are trying to evacuate your A/C system on your car and boil off any water or liquid freon… pulling 10 microns is great. But it is NOT good for keeping your resins from boiling. Most vacuum gauges are worthless below 100 torr unless they are electronic and expensive. You could be pulling more vacuum than the gauge says.

A fun experiment is to pull a vacuum on a sturdy glass jar half full of water. At room temp, the water will start to boil at around 18 torr or 29.2 inches of vacuum.

Do not try to pull a vacuum better than 29"hg, 25 torr or 3.25 Kpa when vacuum bagging a layup, it’s just not worth the risk of creating bubbles in your resin.