It is the only way that I would do it for multi-piece molds that make seams.

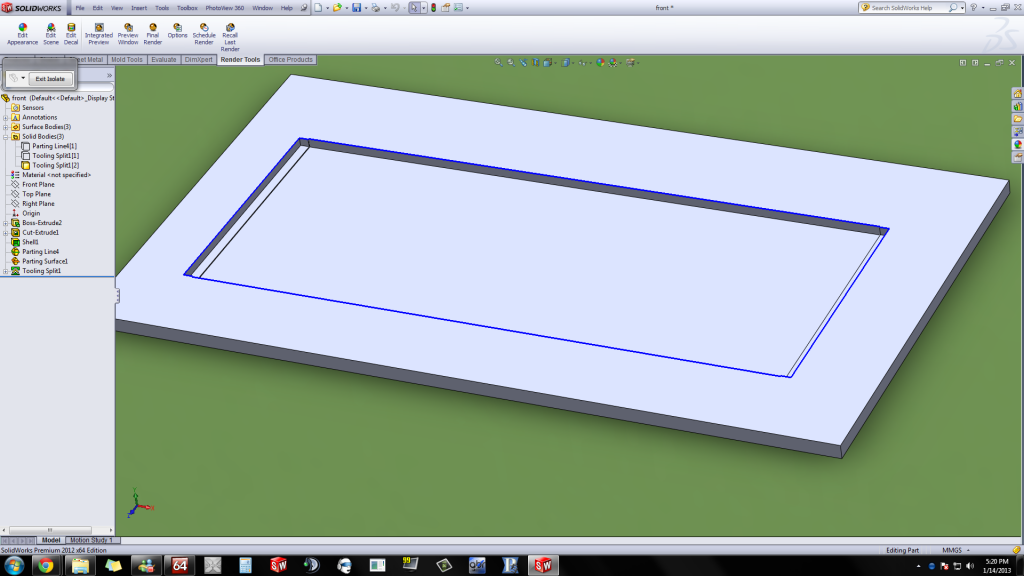

Here is the finished product. This is a case for a Macbook Pro.

wow guys , this is inspirational , now i have more questions like … how you make tubes with 2 moulds and …

if i have a solidworks design , where can i send it to , for someone to make me a aluminum ( or tooling gel/fiberglass ) mold ?

is it expensive? lol like 1k expensive per mold ? (i got a part that is like 550mm x 600mm and 10mm deep )

If the tube is round and straight you can use lathe for aluminum mold machining and it doesn’t have to be CNC. If so, 100€ should be enough.

Maybe you should paste some picture of your piece for some more specific help…

its something like that , it can be edited and all

the depth is 10mm and you can see some trims , those are 1mm …

the size is 648mm x 255mm , and i can edit the mold to make some small flanges , but i was reading that the more space the better lol

i need one like that and the other mold is just a rectangle with the same dimensions but without the trim of 1mm

Thought I would bring this thread back to life (hopefully).

I and my business partner are looking at our options for having some aluminum molds produced. We would like to keep it in the US although open to going overseas for tooling if the cost advantage is there.

Anyone have some referrals they wouldn’t mind sharing with me?

Check with kjcastor here on the forum. He works for Aerodine Composites Group in Indianapolis. They have all the capabilities you would probably ever need.

Jon

Ok thank you.

Aerodyne also in VA. Nicely priced. They are one of the best machine shops in Hampton Roads. The ONLY one I use. Federally licensed by the F.A.A. as well seeing as they also do machine work on aircraft parts too.

5200 W Military Hwy

Chesapeake, VA 23321

(757) 488-2140

I don’t work for these guys but i have used them. I have my own CNC mill now. :love:

yeah , i would like some Quotes for some simple aluminum molds

Which programs do you use to draw and then do molds with CNC? Autocad, solidworks, rhino? What do you recommend for a hobby use?

I use Rhino.

I use SW and have used catia although just a few times

I use rhino too, export the files as IGS to the cncmillers, nice program, but I’m looking into solidworks for the simulation capabilities.

Yesterday I wrote yesterday to the italian seller of solidworks…6500€ + 1200€ for the program…completely out of budget for my hobby works…

Now I have autocad 2004 and mach3 for the miller, but I need a program that dialogue between the two programs (like artcam).

Maybe a friend give me rhino, with this I resolve my problems

i use Solidworks , is super easy to make molds

i bet Autodesk Inventor have the same feature

I create the part first , and decide how to make the mold , creating a parting line , the rest is like a “wizard” you just follow the instructions lol

there are other types of molds , like mold injection ones , but those are more complicated , i just learned how to make simple molds for Composites

maybe i could make a guide or something

Timbuck:

I have seen a few designs where the mold is made and then the plug from the mold, do you recommend this over making a plug directly and then the mold.

I have previously made molds from corian and plugs from tooling board but have never tried to make a mold from tooling board to make a plug, specifically due to some difficulty in working with none flat parting planes.

The other question would be what do you use to create the plug off the mold?

Cheers

Orrin

Hi Orrin

It really depends what you are trying to achieve. I did it this way because it gives me a perfect parting line as I’m making it all one piece and also my parting lone has no flat area’s as such.

When Making an MDF plug for a wing , they have a trough around the leading edge of the wing where the tool bit goes below parting plane to get a perfect LE shape… This is a pain to fill perfectly so I cut that step out.

In my case I also wanted to pull a few planes out of the first CNC tooling molds , although not shinny perfect it gave me time to test the planes while I built the molds… There was no lag waiting to Finnish molds.

Also I made multiple sets of epoxy molds.

Also I’m now doing PU injection molding in the first CNC tooling board molds. I never wanted to just have the money for doing a CNC plug just sitting around. At least now I’m still putting them to good use.

For my these molds I used duratec gloss coat and epoxy / poraver molds , but I still use a lot of high temp epoxy tooling coats as well.

I hope I was clear as mud.  D

D

Tim

Any of you out there using Rhino with the available T-splines plug-in? Don’t have either one yet but I’m gonna.

Jon

i use solidworks , sorry mate

guys , i know SW is kinda expensive , there is a student discount , and i think some colleges gives the student edition (how i got it)

its a great invesment , even for a hobbyst …

its not “impossible” to get  wink wink

wink wink