Alright guys! I want to clear this thing out once and forever.

I want to know, do i need to apply a GEL COAT in to the mold, let it dry and then laying up my materials and infusing the resin. OR

I can lay up all my materials and infuse the resin with out any gel coat??

No gelcoat is needed. It may help surface quality and removal from the mold though.

Thank you,

I am going to make some little parts and see how it will come out. I will post some pics

polyester gelcoat specifically, is just a bunch of problems waiting to happen.

I want to spray my gel coat onto my mold before i will do any lay up or infusion, but i want to know how can i thin my gel coat to make it sprayable?? Some guys are using that Duratec Hi Gloss additive like a thinner. Basically, i have a Gel coat which will cure after 5-6 hours and that Duratec will cure after 10 minutes when i will add a 1.5% MEKR. I just wondering, what curing time will i get if i will mix them 50/50/.? Anyone has any idea?

Thin 2-5% with acetone to achieve the desired viscosity. 3% usually makes even the thickest gelcoats sprayable with a #8 nozzle on the GS100 spray guns. Add the least amount possible to avoid ruining the properties of the coating.

you actually should use MEK to thin or Duratec’s laquer thinner(never more than 10%) for gelcoats. never acetone because it makes it rubbery. I would recommend duratecs VE or PE high gloss topcoats they very thin and get a good bond with epoxy. does not need to be thinned at all. I actually wish it was a tad bit thicker and clearer. It being thinner though helps it flaten but its a pain spraying because you must mist coat the first coat or two before putting on a real coat.

YES, THANK YOU!!! When i mix my gel coat with the acetone it makes it rubbery. IT DOES NOT WORK.

I am talking about this product from FIBREGLAST.COM

Duratec Hi Gloss additive

One more question. Is that possible just to spray clear coat onto the mold like a gel coat and then just do infusion? After when part will come out from the mold, it will need to be clear coated 1-2 times

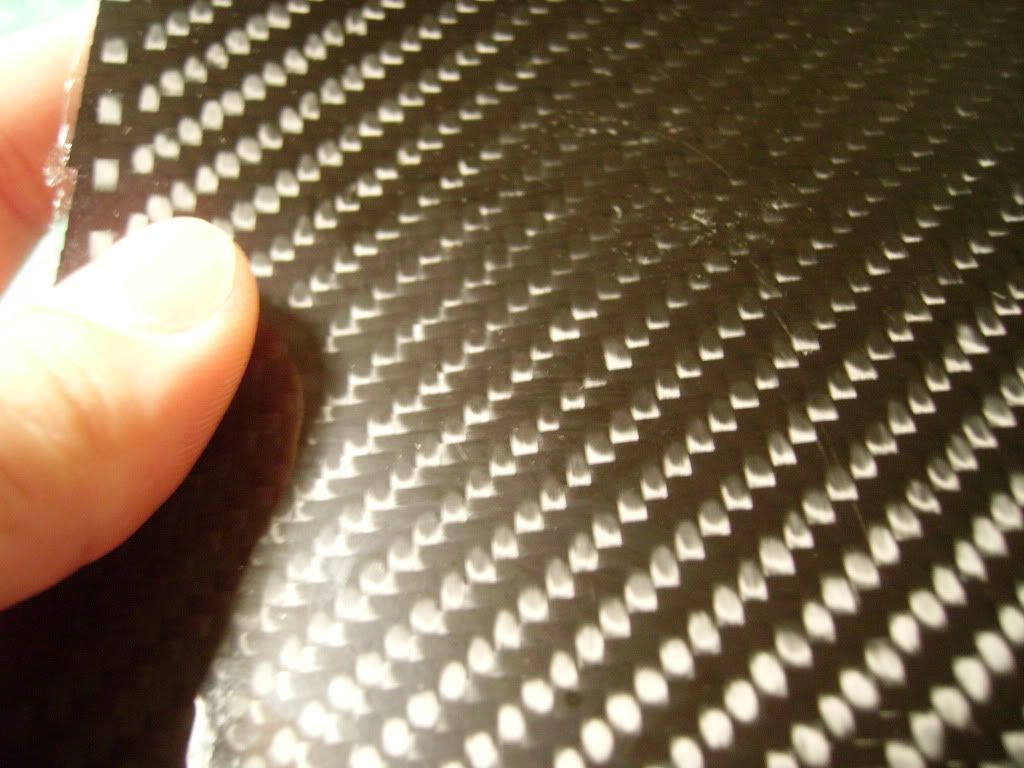

I did that and i got a very good finish. I took off this part from a flat panel today and it still need to be cleared. Here are some pictures.

duratecs hi gloss additive is suppose to be used with a gelcoat up to 50% mix, never straight. it is thin and will reduce the viscosity of your clear gelcoat greatly. you should not have to reduce anymore to spray from a normal gravity feed with a 2.5 tip. you can infuse on top the clear gelcoat but always do test panel prior to making your part to ensure proper adhesion, if you wait to long you will have to sand the gelcoat first. duratecs VE and PE clear topcoats can be sprayed without mixing with another gelcoat or thinning and will have a good bond with VE, PE and most epoxies. hope that helps, good luck

Where can i get that Duratec VE/PE?? Does it have a CLEAR HIGH gloss finish? Basically, you are saying , i can take that Duratec VE and spray it straight onto the mold, let it cure , then sand it little bit and then it will be ready to do my infusion. Does it have a UV in it?

I have a 2.0 HVLP gun . Will it work?

Contact Duratec and ask for your local distributor it will be cheaper than buying off a hobbyist site. It has a higloss clear finish if sprayed thin but if you spray it too thick it will look brownish because its not completly clear unfortunatly. Scotch brite the surface before infusing. The higloss additive with a clear gelcoat will be clearer. Not UV stable, must be clear coated after if its going to be exposed to UV. 2.0 HVLP should work fine with either, fan might be a little small and youll have to spray slower

I do not want to make a THIIIIK gel coat, i just need to sparay something onto my mold just to prevent fabric prints from the fabric. Basically, i want to spray 1-2 CLEAR as possible thin coats then let it cure 1-3 hours then do my infusion. My biggest concern is about mixind two different things when one cures faster than another one. I am thinking to use my infusion resin with that Duratec additive and see how it will cure.

Anyway, i will clear coat it after when i will take it out from the mold

the VE and PE topcoats will cure at 7-8 mils. you might find it harder to get the gelcoat that thin with the additive and cure correctly. also you should use MEKP-925H catalyst with the duratec for best cure.

Right! Here is the thing. That duratec uses 1-2% MEKP to cure, my Epoxy is using 2 parts “A” with a 1 part “B” curing agent.

I am thinking, if i am going to mix all these things together,what will happen?! Another thing, if a gel coat is using MEKP to cure. At that point i can mix them

Have you ever tried just to do your infusion with out any gel coat?

you do not want to mix those together. you can mix the additive with a PE or VE gelcoat, but not with any epoxy. you would spray your gelcoat in to the mold let it tack up and place you material and infuse or if you waited too long you need to sand with atleast scotch brite. You can just infuse with no gelcoat and clearcoat it after, youll get the clearest finish that way. but you may find your mold to dirty quickly any may even have the epoxy attack your mold surface if not properly released.

I do not want to ask some stupid questions, but what is a “PE or VE” gelcoat?

Here is what i am doing. I am waxing my mold 2 times then spraying a PVA. Let it to cure 3-4 hours then spraying 2 coats of a regular UV clear coat. When everything is cured, i am laying up my materials and doing my infusion. The only thing i do not understand, why i can not do that in to that way when i can get a CLEAR high gloss finish?!

After 48 hours, i do a wet sanding (1500 sand paper) then spraying 2 more coats of clear

By the way, i newer sand my gel coat in the mold (which is a regular clear coat) It sticks VERY WELL in to my infusion resin

PE is polyester, VE is Vinylester. Personally I do not like PVA at all. your best to use just wax or even better semi permanent sealers/release. Im a little confused on your exact process but if its working for you than thats great go for it. If your asking why your part isnt shiny out of mold it is probably from the PVA, just waxing or semi’s will fix that. the higloss additive will only work with PE and VE gelcoats not clear coats or epoxies. Im not too sure why your sanding with 1500grit paper then clear coating again, you should either sand with 400 grit and spray with clear or sand up to 2000+ and polish.

Okay, i understand right now.

I am using 1500 grit paper, because my “gel coat (clear coat)” is thin when i am taking off from the mold. To make the surface little bit thicker and more shinier, i am sanding a little bit then spraying more clear coat. If i will use a 400 grit, i will damage CF under that clear coat.

Why you do not like PVA?? It helps me alot to prevent any epoxy sticking in to the mold. Also, demolding process is very easy

pva is a great solution, but if you have a mold with a perfect surface, sanded and polished, wax will always leave a better surface, and demold easily too. personally i use pva when i make molds out of parts and want to protect the originals. after that i sand and polish the mold, and apply wax.

not to start a dispute so if NOT using acetone works for you then good. I have thinned clear gel coat with 5% acetone and had no problems with the hardness or finish.

If MEK works best then stick with it.