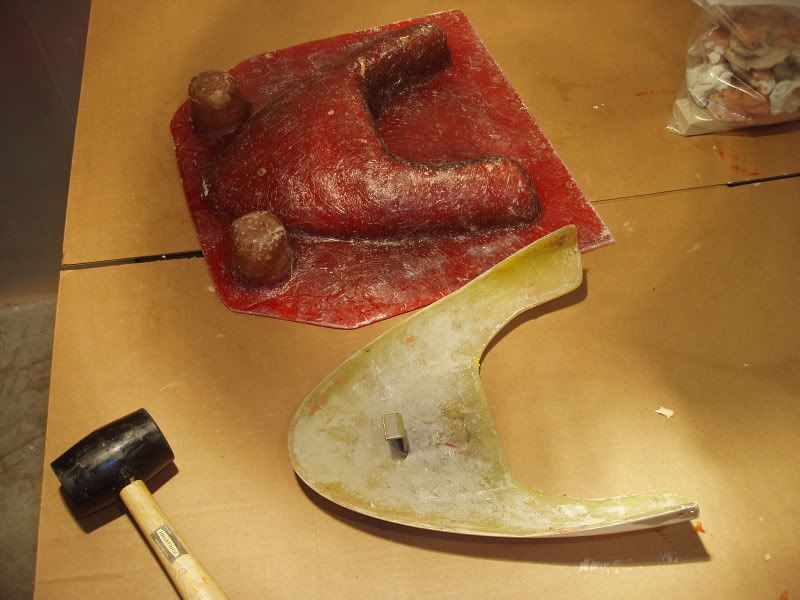

I have tried my first mold and it came out sucessful! There were some touch up spots but nothing that effected the actual finished part. I have learned some things to imporove on for my next mold.

My next step is infusion and I have some basic questions. I did try to search and couldn’t find excately what I am looking for.

Below I have a list of parts:

Clear Gel coat-we want to watch the resin as it seeps into the fiberglass

2X2 twill cloth 8.5 oz. seems thick. (US C)

Peal ply release fabric (US C)

Flow media.

Spiral wrap

Breather cloth (US C)

Sealant tape (US C)

700 Vinyl ester resin from (US C)

3M #77 spray adhesive (US C)

Nylon bagging film (US C)

Tees for vacuum and resin

Most of the parts I am going to try to acquire from US Composites.

My first question is where do you guys think I should buy the remaining material, gel coat, flow media, spiral wrap, etc? Am I missing anything as far as materials?

Next question is I am unsure of how many layers of fiberglass is necessary. I am thinking of using the 8.5 oz and my orginal part is 1/8 of an inch thick. How many layers would it take to get around 1/8".

Thanks guys, I know these are really basic newbie questions but anything can help me at this point!

I have attached pictures of the mold and the vacuum pump