Currently im using the cheap 2" economy brushes and throw em out after every use… 2" wide and like 3/8" thick = very time consuming to go over a big part…

http://www.harborfreight.com/pack-of-36-2-inch-industrial-grade-chip-brushes-4182.html

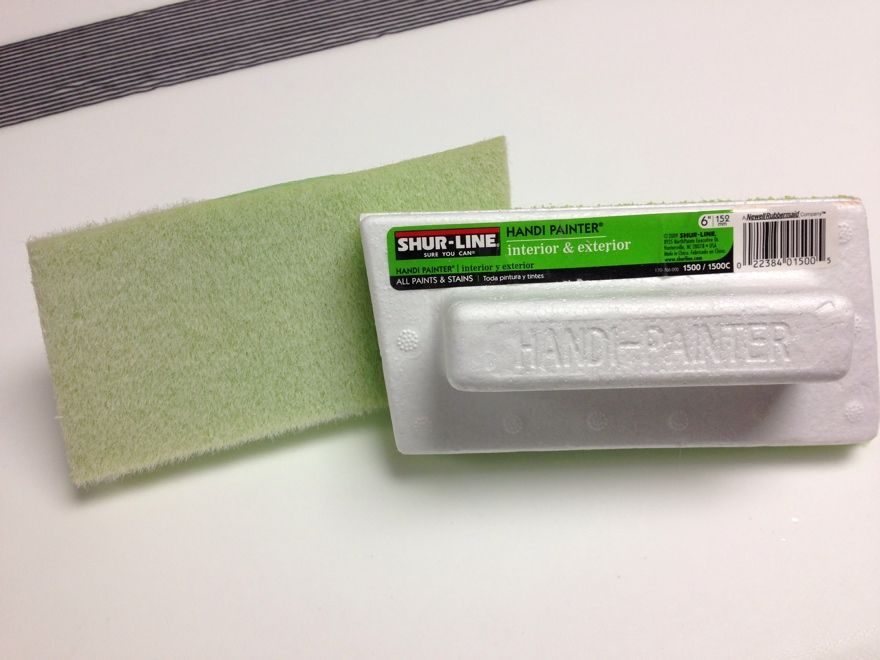

Do you use the disposable route or buy better brushes and reuses them? Im thinking if i can reuse a more expensive brush (like for painting) i can get a 3" by almost 1" thick brush which would mean A LOT less stippling and more area coverage…

also does anyone know where i can get a roller with the groves lengthwise vs the ones with groves around the circumference of the roller?