A salesman I’ve been working with was telling me that although infused carbon laminates appear to be fully wet out they are not. When cut and put under a microscope there is dry fiber and the resin hasn’t fully gone in-between the fibers. He discouraged me from infusing. I love to infuse because I am terrible at wet vacuum layup. My thought was could the small bubbles and voids in the wet layup part be superior to the great looking infused part? If so how far off from full saturation is it? I have heard that Vectorply has a micromesh that goes in your part in between the layup that will fix this saturation problem.

The pressure bulkhead for the 787 is infused at PAG. They call it VAP but it’s basically just infusion.

salesman :rolleyes:

I have never done infusion and am just learning the details about it, but- I went to my GE LM turbine training class in Cincinnati a few years ago when they were using vacuum infusing to create the turbine blades for the GE 90 aircraft fan. It is the most powerful turbine powered aircraft engine ever made (they were actually building the GE115, a derivative of the GE 90 engine slated to replace the 90 sometime in the future). I had never seen infusing before, and it was fascinating to watch, especially with the giant turbine blade (they were doing it in layers, and it was really cool). I asked the guy why they were doing it that way instead of wet layup like they do their giant windmills, and he said that the infusion process was the best way to get the reinforcement material completely penetrated and completely saturated with next to zero excess. So tell your salesman guy he’s full of it… lol

I can imagine the laminate the Salesman produced was not fully wetout.

Although there still is a void content it is much lower than wet layup when done right.

Hmmm, that bit about the GE90 sounds odd. That might have been a prototyping facility? CFAN is the producer of those carbon blades (based down here in San Marcos, TX) and they use pre-preg. There is a nice video of it here:

[ame=“http://www.youtube.com/watch?v=eoNySabChvA”]GE90 and GEnx Composite fan blades - YouTube[/ame]

It is a prototyping facility. I should have said that. They were working on an upgrade to the GE90. (looks like from the video that their efforts became the GE90 115B- I was there in 2006).

Excellent video… I learned a few things I can do to speed up or improve production in my own shop.

Good video. Sometimes it’s a relief to see something properly made among the tons of videos on youtube.

Did you notice the insulating blankets onto the mouds in autoclave?

What is the purpose of doing that? To make heating slower and more uniform?

They are applied on open moulds to let the laminate to reach the same temperature gradient on both sides of the laminate stack.

Otherwise the part will come out warped.

The use of strongly unbalanced stack of uni tape will worsen this behaviour.

Coefficient of Poisson tells you something?

Very interesting video…Roberto so truee…youtube is full of crap how to videos

Not achieving full wet out can be an issue when infusing very thick all carbon laminates. When infusing a 1+ inch thick carbon laminate with only flow media over the top you will likely see that the resin will not fully penetrate the entire laminate stack.

Not true.

Using the proper technic, you can get perfect results also in very thick layers stacks.

Just last week I made a test panel to prove it myself.

Ps: please resist from the urge of typing at any cost.

If someone has not been able to get good result with a job, it doesn’t really mean that nobody else could be successful with that.

Wow Roberto, seems like a must have struck a nerve. I can assure you that it was not my intention and my apologies if I offended you for some unknown reason.

Anyway, if you reread my post you will see that I said that not achieving full wet out “CAN” be an issue which means that it is possible that it also may not be an issue. Also, nowhere did I state that nobody else could be successful at infusing all carbon laminates that thick so I am not sure what you are referring to.

In any case, congratulations on performing a successful test panel but I think people should also be made aware that there can be problems when infusing thick carbon laminates and there are both products and strategies that exist to prevent them.

This is all good to hear I’m glad my products aren’t destined to fail because I infuse haha. Does anyone know why there is micromesh to put in your laminate? Does it create a stronger more saturated laminate? Or does it just make the process easier?

Pre-preg, wet-lay, infusion can all be done well or poorly. I’ve tested samples from all three techniques that were excellent and some horrible. It all comes down to who did it and how they were done.

The micromesh can be added to make it easier to achieve full wet out when infusing, particularly with thicker carbon laminates due to the small filament diameter of the carbon fibers. I wouldn’t call the micromesh a flow media by any means but it also helps slightly with flow. A lot of people who post here make smaller parts/thinner laminates and use a clear gel coat/imc so it is obvious if the laminate is not fully wet out. However, if you are infusing a thicker carbon laminate on a large part that is color gel coated there is no easy way to determine if the laminate stack is fully wet out without cutting into the laminate.

And just to be clear, with proper techniques and controls you can typically achieve full wet when infusing carbon laminates out but I would say the micromesh makes it easier.

Aparently you couldnt resist the urge of typing at any cost!:mad:

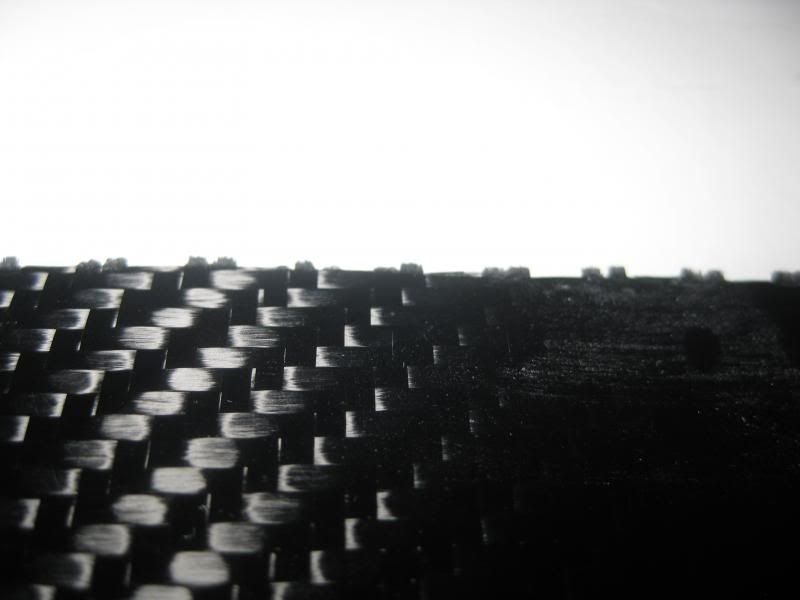

:D:D:D:D:D:D:D:DI have never had a visually dry infusion until now that I had asked the question. I just swiched resins from PT@W epoxy 450 cps to CCP epovia 90 cps. you would think that the difference in viscosity alone would produce a more saturated laminate, it was completly opposite. Infusion time with epoxy was about 45 min and with CCP vinylester about 25 min. This is an infused core with holes drilled in the core and scored on the mold side. The vinylester reached the edges of the core on the mold side before the flowfront on the top of the core. There was no pinholes in this infusion and had great vacuum with very little leak. The pictures below show my dry problems. The first picture shows fuzz on the end of where I trimmed with diamond blade bandsaw. It appears the only fuzz was the 2x2 that directly touching the mold. The inner layers seemed fully wet out. The second picture show the laminate in the light you can see a slight matte finish where the 2x2 directly touches the mold. This was a pain to trim because it pulled up fibers until the weave changed directions. The epoxy laminate didn’t have any matte problems. I would switch back but vinyl ester is cheaper and easier to use. I used chem lease for release system and slightly wiped it dry a few min after applying maybe it contaminated the carbon. Maybe if I wipe it off more thoroughly next time. Since dry laminates are all technique what do you guys think?