I am planning to use a honeycomb sandwich core but was wondering about the strength of the core when used vertically.

If I were making a CF bookcase, the CF covered core could easily be used for the shelves, but what about the vertical walls of the bookcase? All the load would be pushing down on the sideways oriented

honeycomb, does this make sense? Kinda like crushing a can on its side vs standing it up.

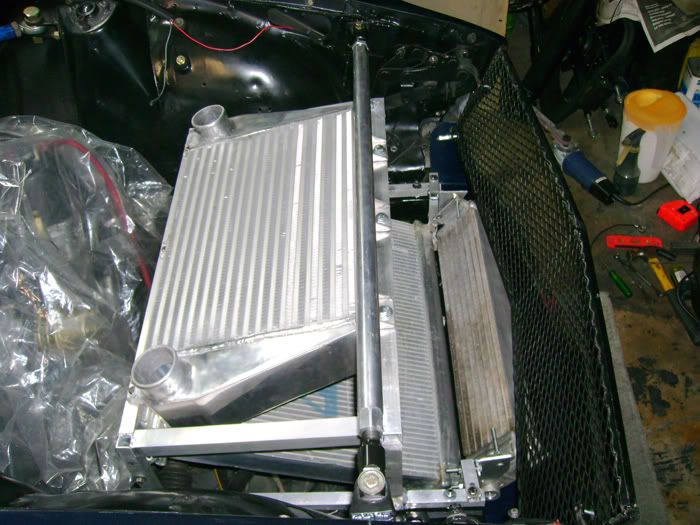

Also, I’m not really making a bookcase. This is for a V-mount configured radiator and intercooler. How do I determine if my core is strong enough before actually laying the pieces up? The water filled radiator and the intercooler are pretty damn heavy, plus vibrations from the engine/road, and engine heat…maybe I should go back to the original plan of using aluminum sheets.

Thx!