Hey gang. I realize this isn’t technically a composites question, but I’m having issues with PVA.

I am molding my fenders to make some custom fiberglass versions…it will be a 4 part mold due to the multiple negative reflections:

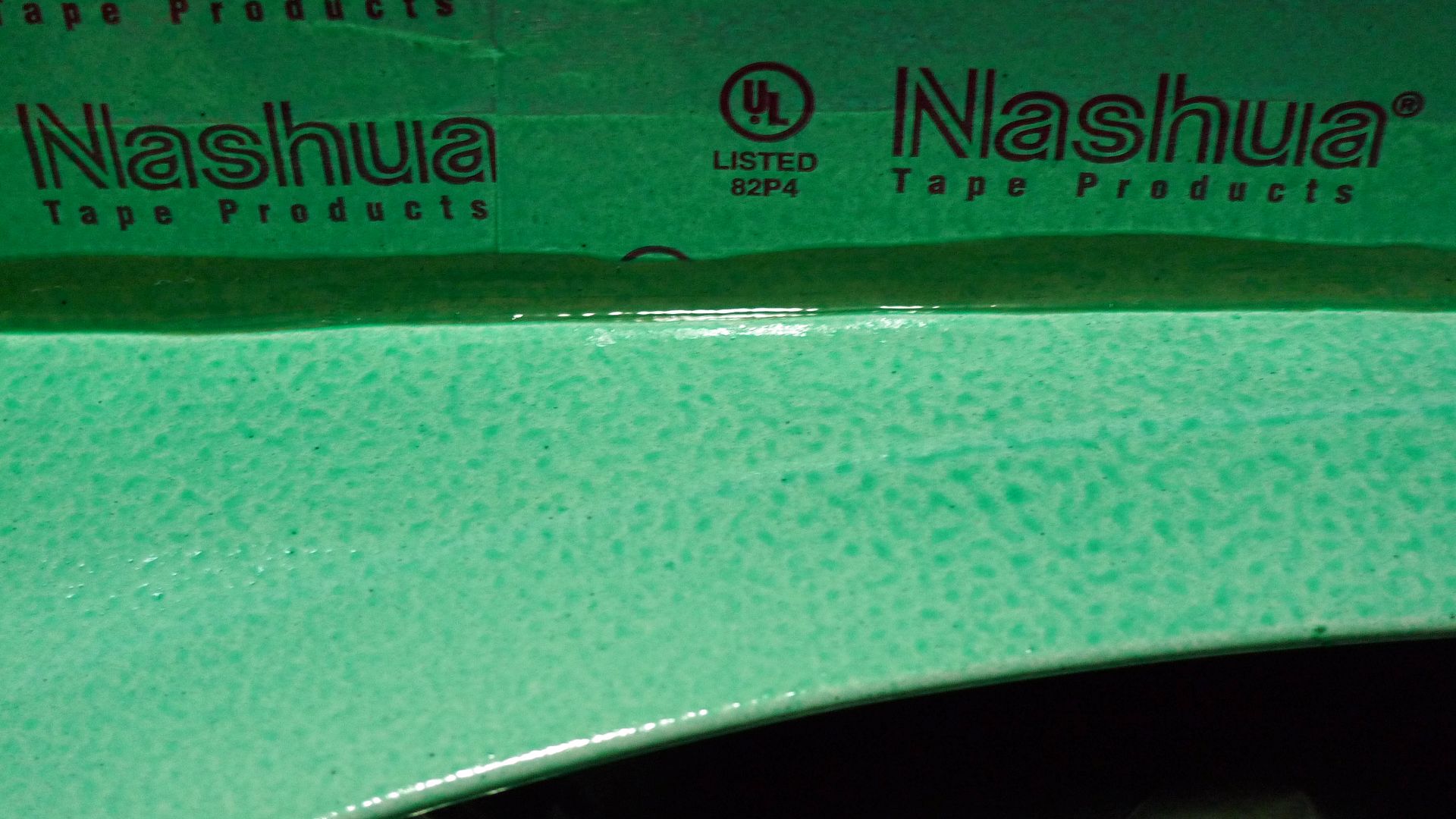

And here is how the PVA looks:

I am spraying with a compressor and gun. The psi I’m spraying it is between 60-100 (it’s actually a tiny compressor for a nail gun and the pressure drops off pretty rapidly…but I stop before it gets below 60 psi).

Last time I applied the PVA, I sprayed 10 coats (30 minutes between coats at ~60 degrees Fahrenheit)…but I noticed that it never turned into a film even after 3 days…it just stayed wet.

My second question, do you keep PVA in your gun between coats? Or do you break your gun down and clean it between every coat? That would get REALLY tedious…but I’m noticing grit in the plastic filter in my gun and this grit is showing up in the surface of the PVA I’m spraying.

Thanks in advance.