Hi all,

I am new to this site, didnt know it existed to be fair!

I am in the uk and am building a competition circuit R32 skyline gts-t.

My main focus is to remove a lot of the weight.So far i have:

-10 square meters of fibreglass finsihing cloth

-10kgs of polyester resin

-fibreglass roller

-lots of cheap brushes

-buckets and jugs for measuring and mixing

-some normal car wax

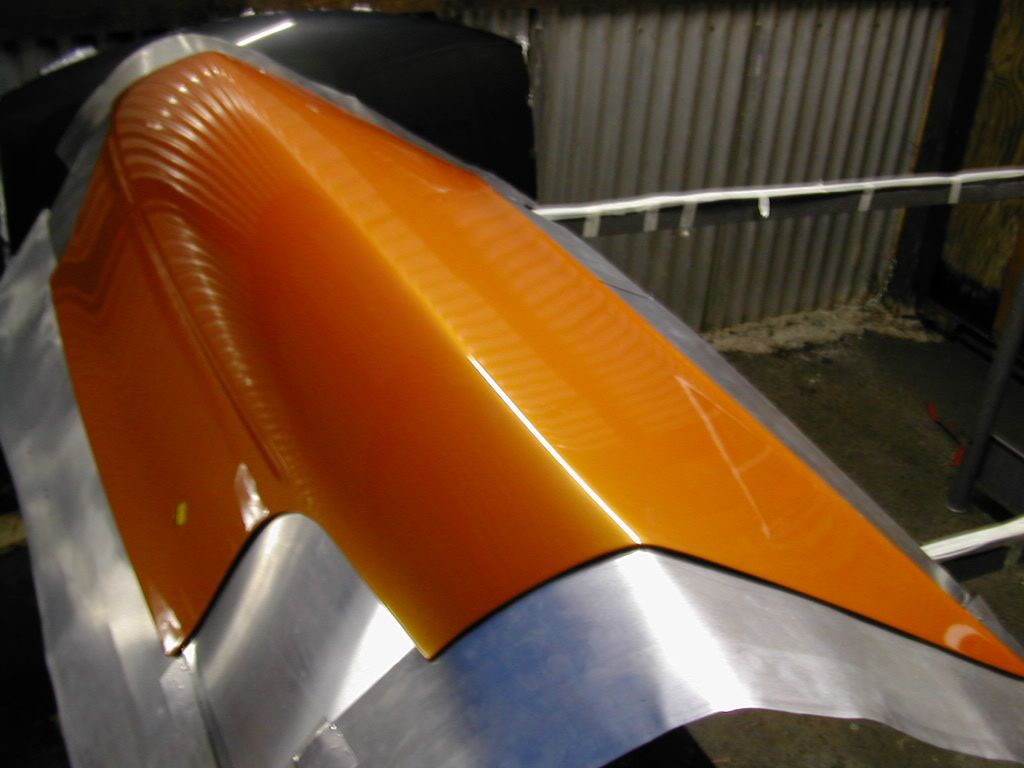

I am attempting to make a fibreglass mold for the boot/rear hatch on my car which is a straight forward shape. Am i using the right stuff, or do i need epoxy resin as i cant find it anywhere at a good price. If i need epoxy can anyone name cheap suppliers in the uk, preferably in the midlands.

I have waxed the boot 5 times now and applied 2 layers of cloth with lots of resin, i then rolled out the bubbles and ensured it all went see through with resin.

This has dried now, but should it set from normal room temperature or does it need heat(i have read somewhere that i might need heat on this to cure) to cure?

I now need to get something stronger on the back of this which i am waiting for delivery on which is chopped strand matt.

Once the mold is mad (if it works) should i just fibreglass inside it or do i need to wet & dry it smooth and wax it again? also got ova release agent coming.

Thanks John