Hello. Even the great Nikola Telsa didnt get it right from the start at times…so My infusion failed. Here are the problems that occured.

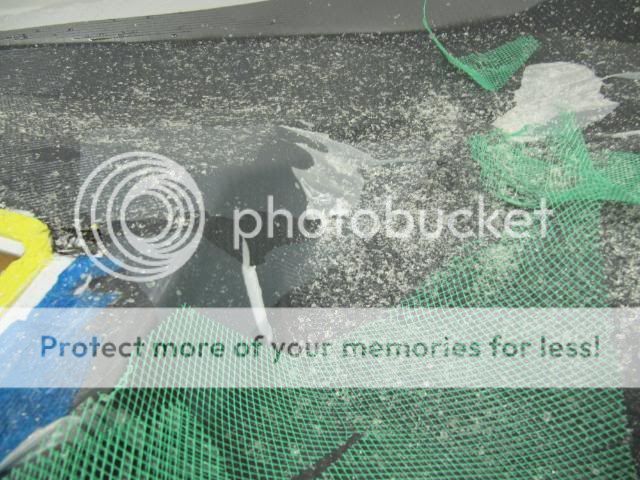

1st thing was I had bridging in the Peel Ply. I realize that I had bridging and ripped everything off and re-did the peel ply layer from scratch and I made sure that there was extra though it was still bridging in the some corners, see pic below.

In the pic do you see where the spiral wrap does a U, in that recess I had bridging.

Any suggestions or advice about bridging in the Peel Ply layer??

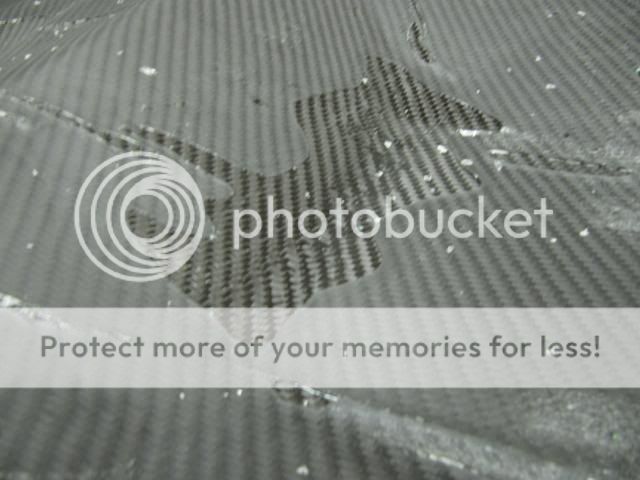

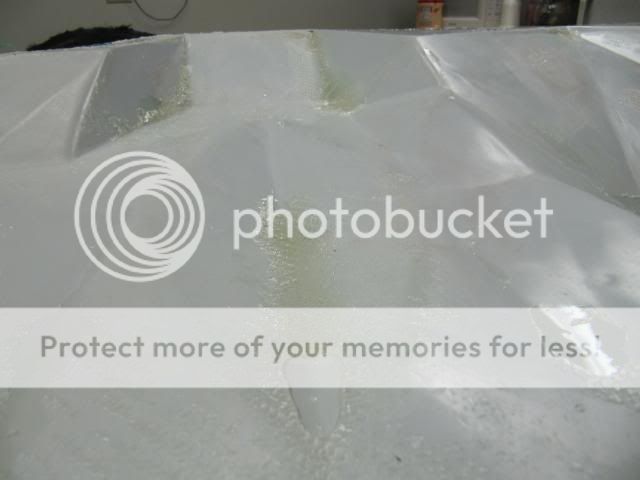

Secondly, I had a flow problem I tried to make the flow go from the back to the front. The resin went in great at first, though, it was not properly flowing to the very ends. I do have a second flow pattern now to correct this. I see where I error-ed.

Thirdly, why is it when I clamp off the feeder line, the out-flow line is still pulling resin thru the infusion. My guess it because I air still trapped in the mold. Correct me though, isnt the flow suppose to stop when clamping off the infeed line?

Those were the heart of my problems. I can post more pics if needed, it was getting late and I want to just call it day, so I skipped on the pics