I have come to the conclusion that the way i have been making molds is incorrect as far as the flanging goes.

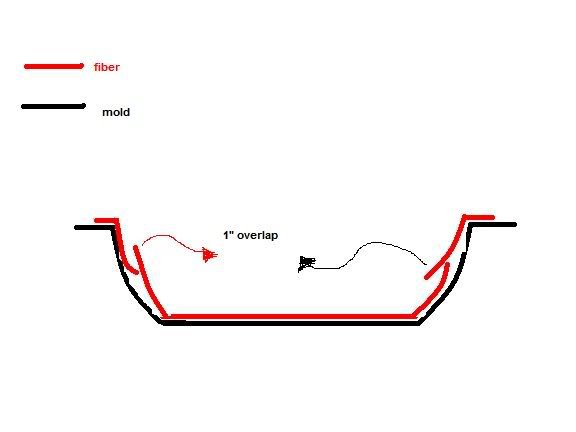

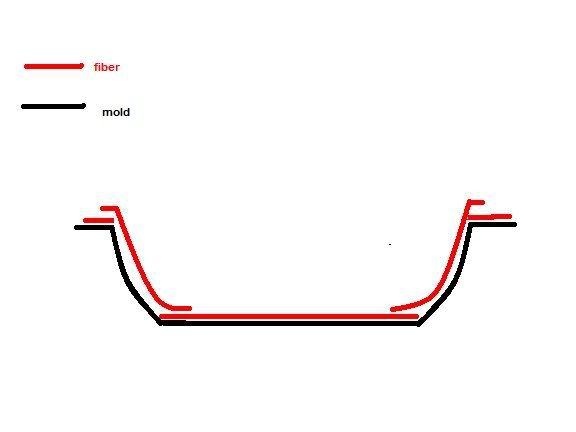

My flanges are 90 degrees to the mold/part cavity. This is causing bridging and dry edges along the edges of the part near the flange. So when the part is trimmed to size there are dry edges there or seriously bridged or bubbly edges.

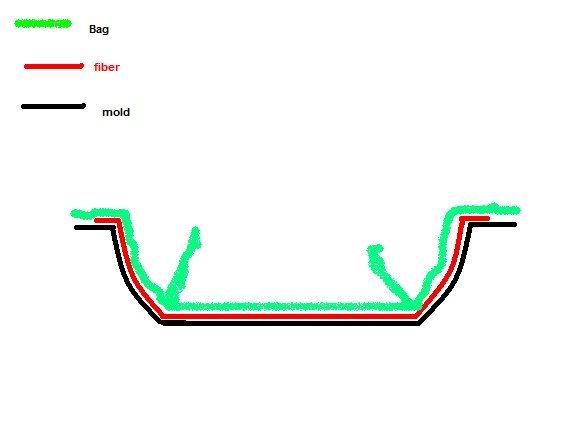

I’ll put up a drawing of how i have been making my molds, and this has proven to be a problem when making the parts. The picture will explain.

I post this so no one else makes the mistakes i have, or if you are having the same trouble you now know why that is.

What is happening, I think, is the bag is wanting to pull down tight on the laminate before it can take proper shape to the mold… oncee that laminate is sandwhiched in between the vacuum bag and the flange there is no way for the laminate to be pushed down tight against the mold cavity, so bridging happens and dry bubbled up areas occur on the cured part.