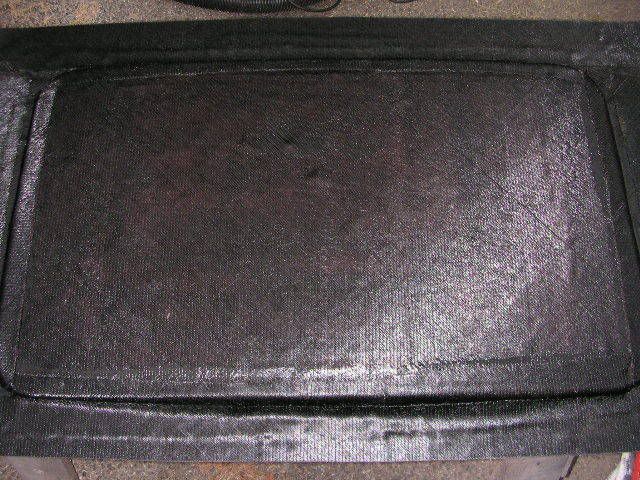

Pictures are of a mold that i had someone else make for me. He said that the mold was ready to go and that i could start laying up the carbon fiber.

After close inspection i see tons of flaws in the mold and i am wondering what are my options.

I am trying to figure out if i need to have a new mold made?

-----OR

If i can repair this existing mold.

Here are two of half a dozen pictures i have:

As you can see. The issues are the gaps between the actual part and the mold. Can i fill these gaps with Bondo and the bondo actually holding?

Is there a type of liquid filler that i can inject through a plastic needle to fill the spacing? Bondo was wayy to heavy to get through the needle of the dispenser. Can i make the bondo more viscous somehow?

Do you think i should have a new mold made?

I was also told from others that the mold was not strong enough and that i would need re-enforced it, so that i can tape the bagging directly to the mold (instead of an envelope style mold).

If the bondo can hold, i want to lay up a prototype in fiberglass to make sure all the contours and dimensions work well. If not, i was thinking after i bondo i could add another layer of fiberglass to make the surface layer stronger, then spray a new sealers and final coat to have a new strong finish. My only worry with this idea is, the dimensions of the final product will be slightly smaller because of the change in the size of the pocket on the mold.