This is my second project so far using fiberglass. I am practicing with fiberglass before I waste a bunch of cf. I am using my 14" air cleaner lid from my Corvette as a mold to make one out of fiberglass and eventually carbon fiber. The problem I am running into is getting a nice smooth edge on the outside. Anyone have any suggestions on how to get a better edge. I am just doing regular layup.

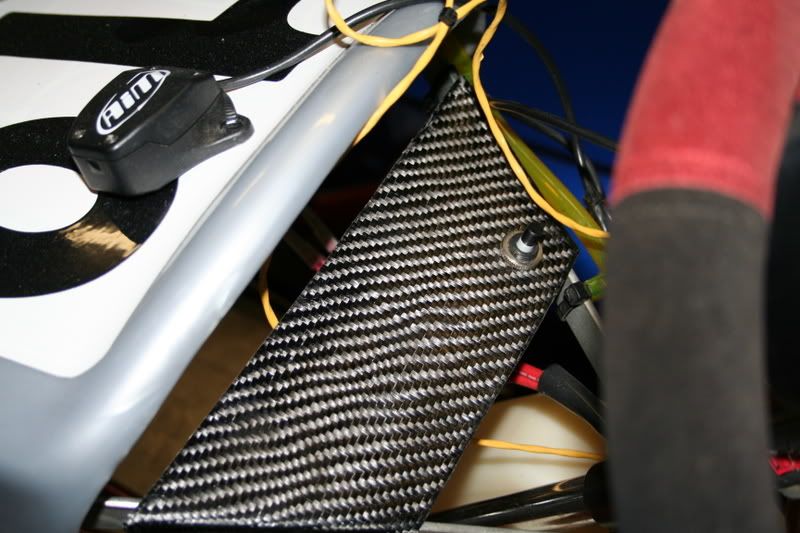

Here is my first carbon project, ignition and start button switch for my kart. Still needs to be cleared and mount the start button.

Brush on a thin layer of resin, spread it around, and continue to brush and spread it evenly until it becomes quite sticky, I like to wait until ‘hairs’ form when you try pulling the brush out of the resin.

From there, I use the brush to press the reinforcement down into the resin, the idea being that the resin will be sticky enough to hold the reinforcement down. Add more resin over the initial reinforcement layer, then, just add further layers of cloth and resin as needed.

For best results, vaccuum bag the part as well.

thats called bridging and if you do infusion work youll run into less of it but its still really easy to have. I still get it once in awhile and it drives me nuts.

The previous techniques are great as well.

this is what I do as well. Works very well. Also becareful of the viscosity of your resin. Thinner resins will pool more in the middle and drain from the sides leaving dry or bridging spots