Is there a theortetical limit to the thickness of a CF layup?

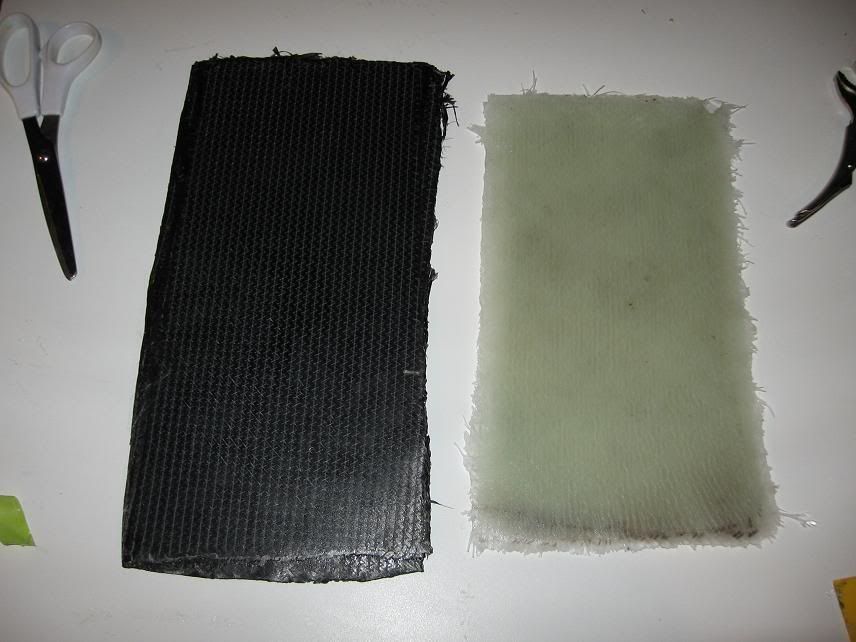

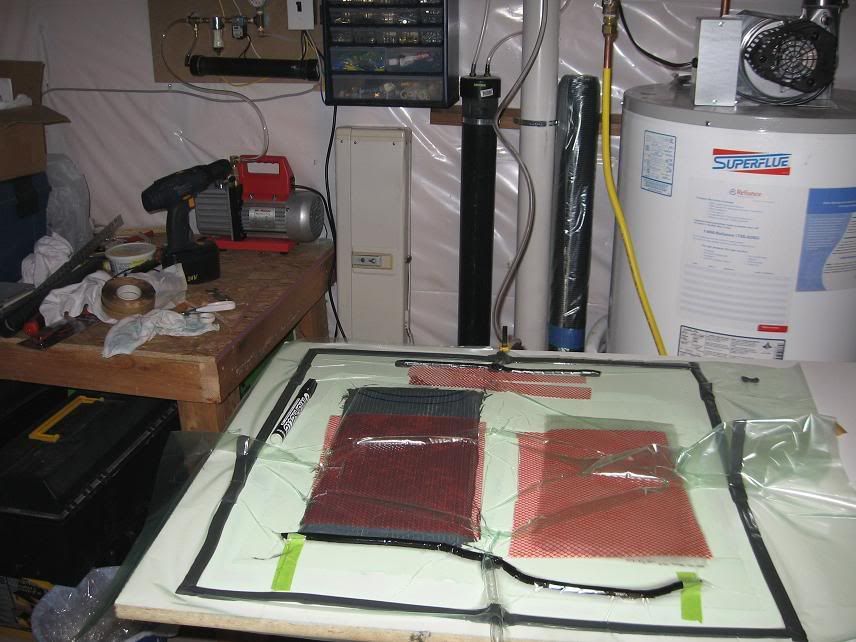

I’m thinking of makeing some structural parts for the boat, backing plates, stern bearings etc. and would need to layup up multiple layers of CF to get the desired thickness, 1/4" to 3/8" thick in most cases. I’ve got some very heavy multi-axial fabric Werks sent me that I guess is about 20 oz/yd and 4 layers of that is 1/4" dry. I’m going to infuse that stack tonight to see how it works. I’ll have to cut it apart to see if the infusion actually gets through all the layers.