There are multitudes of different types, tow sizes, and uses for carbon, but I will try and put everything into a few “short” paragraphs (used to work for Toray, now with a weaver/stitchbonder).

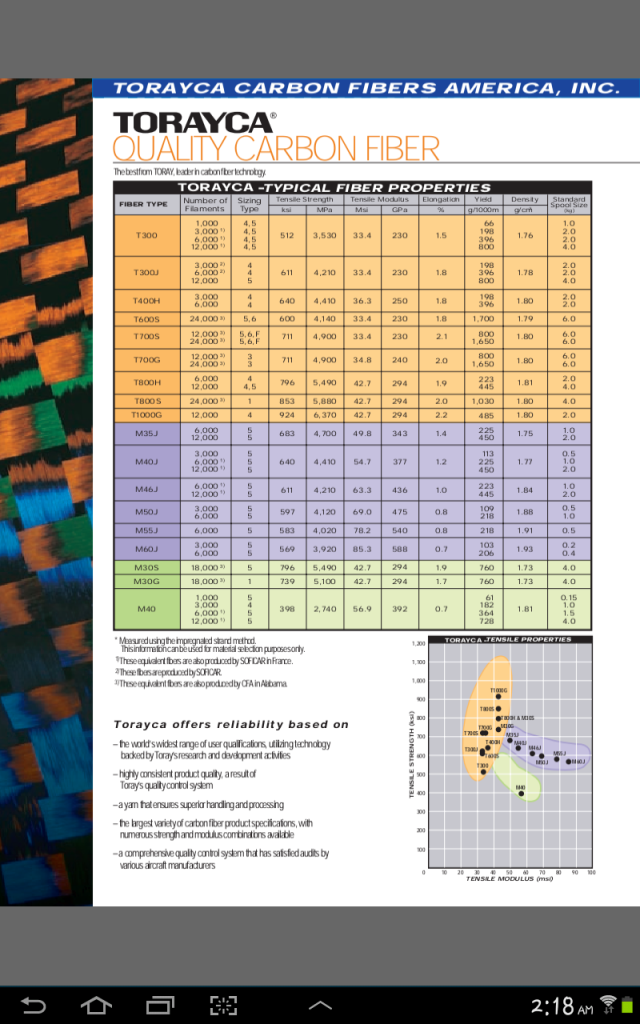

Carbon fiber (for use in composites) these days consist mainly of PAN (polyacrylonitrile) or pitch based fibers. There are others such as Rayon based and lignin based, but those are either outdated or in various stages of development. PAN based are the majority of fibers you see in the market and are generally classed as high strength/standard modulus, intermediate modulus, & high modulus. Pitch based fibers are more specialized with the low modulus versions mainly used in thermal management applications, and the ultra high modulus stuff is typically used in high end sporting goods and space applications.

Most of what is seen in the market place is the “high strength/standard modulus” carbon. This includes T300, AS4, T700S, STS40, Panex 35, etc. These fibers are around 95% carbon (the rest being remnence of the PAN precursor) and are generally a combination of cystalline and amorphous-like carbon molecular structure. The crystalline part generally gives the fiber its modulus while the amorphis part gives it its strength. All fibers in this category have filament sizes around 7 microns in diameter, but their cross section shape can vary (T300 is more kidney-bean shaped, T700S is round, some have striations, etc.). Quality for these fibers isn’t necessarily based on their properties; T300 was developed in the 1970’s and is used in many spec’ed in aerospace/defense type applications (i.e. the fiber manufacturer can’t change any of its properties or how its made). T700S was designed for better tensile strength and elongation, mainly for pressure vessel applications and other industrial apps. Both are high quality fibers, but have different strengths.

The intermediate modulus fibers are what’s typically used in primary structure aerospace applications (Boeing 787 fuselage) and include fiber such as IM7, T650, T800S/T800H. Unless you are in high end aerospace, military, or pressure vessel apps, you typically won’t run into these fibers as their cost is about double that of standard modulus (roughly). Filament diameter is reduced to 5 microns which makes them even harder to infuse than the standard modulus versions. Carbon content is again in the 95% range.

High modulus carbon is made on a low volume basis and is typically only used in very high end applications (space craft, high end bikes, etc.). These fibers are “graphitized” so their carbon content is around 99% and are sometimes called graphite fiber. Modului are high, but strength is reduced due to the higher degree of crystallization. Cost for these type fibers can run into the $1000/lb range…and that’s before its prepregged or put into fabric.

To address fiber quality again, the higher quality fibers have lower variation or properties (strength, modulus, yield, etc.) and are processed (woven, filament wound, etc.) with very little fuzzing/fiber breakage. Quality can also be address by how well the fiber pays off the package (bobbin), or how well the fiber bonds to the given resin (more dealing with the surface treament and sizing).

All carbon fiber is black…all of it is black no matter what grade it is. If you see colored carbon it either isn’t carbon, or its the resin that is colored. Epoxies work best (as that is typically what the sizings are based on), but you can use carbon with high-end full vinyl esters with some good results.

All in all you will most likely use standard modulus carbon. The small tow (3K, 6K) fabrics are great for cosmetics but can be expensive if you are actually using it for structural applications. 12K, 24K, and 48K tow sizes are typically used outside of aerospace apps when people want the performance and don’t care so much if its pretty.

So much for my nutshell…