Here are some pictures of an ABS plastic vehicle ashtray cover which I would like to skin/wrap in 2*2 ProWeave carbon fibre. (the back of this cloth is partially impregnated with a resin binder to keep it perfectly aligned).

Here is the process I went through on attempt number one with a spare ashtray cover I purchased from my dealer:

-

Key the outside with 240 grit paper

-

Apply black basecoat to the main flat outside area and wait until tacky

-

Apply carbon fibre cloth to the outside main flat area, press down and allow to cure

-

Apply base coat to the outside and inside edges

-

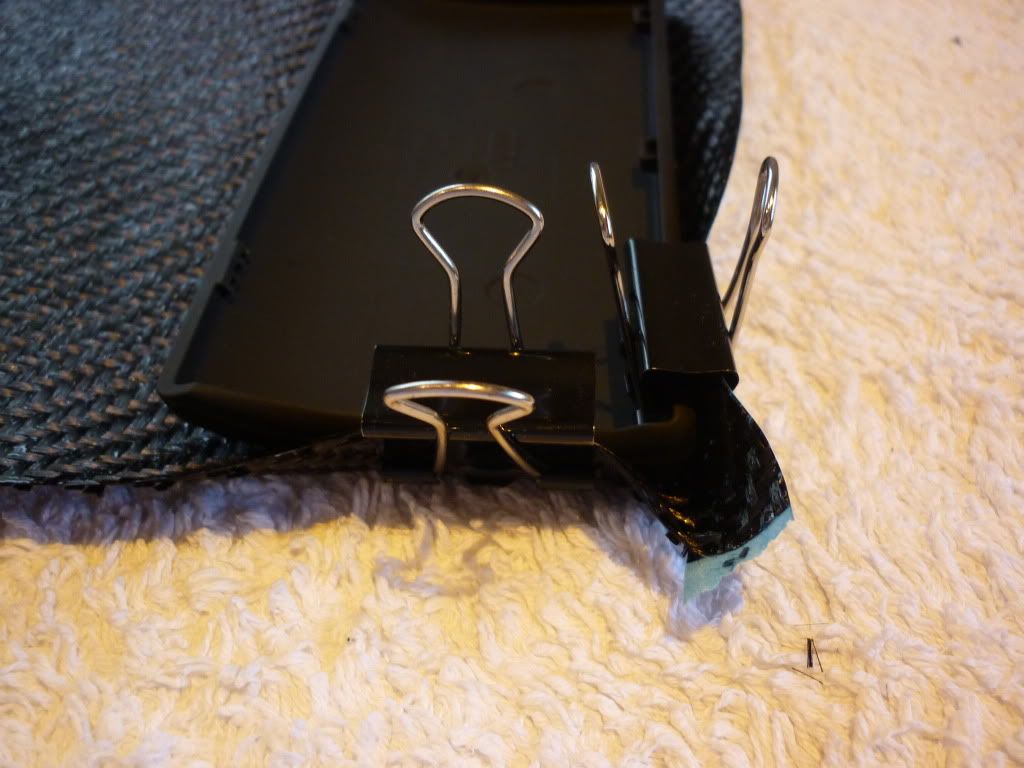

Wrap cloth around onto inside edge and secure with bulldog clips

-

Trim corners by cutting a square out of each corner

-

Apply base coat to corner of ashtray cover, wait until tacky and press down cloth - this turned out messy and not as neat as I would hope. Is this down to my impatience when trimming or is there a better method?

I wonder if there is a better method I should be using for these corners please?

Here are some pictures which show the complex nature of the corners.

In this picture I have bulldog clipped the cloth onto the corner of the ashtray cover dry to illustrate the cloth at the corner. Is my best option to go ahead and neatly cut down on either side of the cloth to a point then stick it down? the rounded corner seems to make things difficult.