Hey guys,

I am basically making a carbon fiber tub. It measures 36x22x22 inches. The mold I have made and used once has about a 4 inch flange around it as well. Using infusion grade epoxy and the stack is just IMC/3k 2x2 CF/uni CF/Soric/3k 2x2 CF

My first infusion went ok but i know it could be far more optimal.

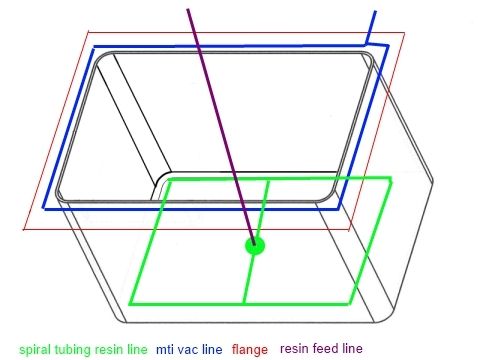

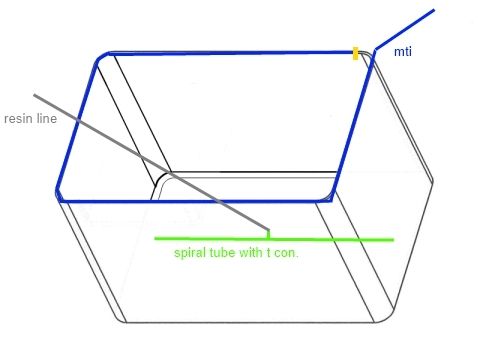

Sorry for the bad diagram.

I thought about trying a resin line along the length of the flange with the mti hose on the opposite side. Then maybe 2nd resin line in the bottom middle of the tub for it to have a fresh start to go up the vertical wall.

What do you guys think?

that’s the way I would do i.

that’s the way I would do i.