hey guys,

So I’ve been trying the infusion 6 times and out of those 6 i only got a semi decent part. As some of you know from the previous post, I was having trouble with the polyester resin. A few days ago I bought some systemthree mirrorcoat epoxy (700 cps) and switched from using my polyester laminating resin.

Setup:

1.5 cfm pump

Mold–>Peel Ply B --> Flow Media (airtech green) -->Bag

Degassed epoxy

Attempt 1: Polyester resin, mold, peel ply b, flow media bag - disaster nuff said

Attempt 2: Polyester resin, mold, peel ply b, flow media bag - decent part, but many tiny bubbles in resin: instructed to use epoxy

Attempt 3: Polyester resin, mold, peel ply b, flow media bag - waited to long and polyester resin cured in line

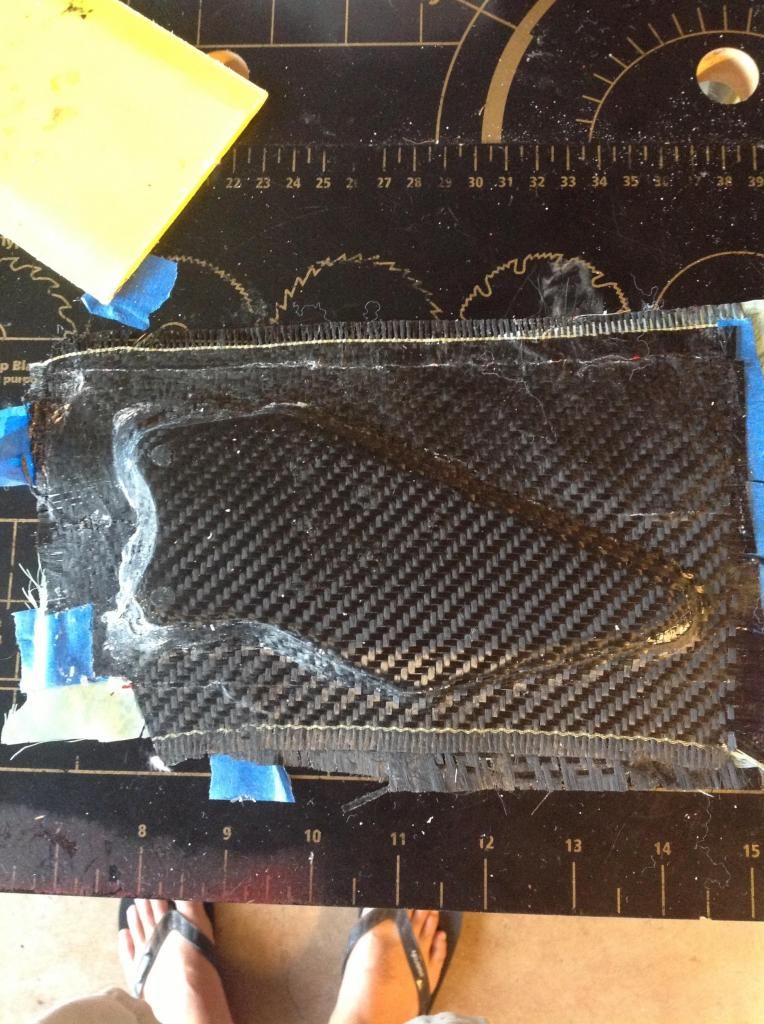

Attempt 4: Epoxy resin, mold, peel ply b, flow media bag - see below

Attempt 5: Epoxy resin, mold, peel ply b, flow media bag - infused properly, pending results

Attempt 6: Polyester resin, mold, peel ply b, flow media bag, envelope bagged - see below

On my first attempt with the epoxy (Attempt #4), I added the wrong ratio of part A to part B so it gelled before it could get infused. Today, I put in the correct ratio (Attempt #5), and it seem to flow through nicely, but I have my doubts right now about it.

Also, I did what sammy said and for kicks, did a gel test on the polyester resin. I was able to double the amount of time to ~20 minutes working time using 0.5% ratio of MEKP to polyester. So I made a second infusion today (Attempt #6). This time I tried envelope bagging that mold. So it went great, pulled 28.5 mmhg. I have been making so many mistakes, I have the little parts down. So I was able to degas the resin. As I infused it, it looked like my first attempt where it looked like it was infusing to fast and there was a lot of bubbling throughout the part as it was infusing. Since my mold was small, I was not able to put the resin outlet line away from the infusion mesh. It was almost touching the mesh. Is this the reason for the massive bubbling while infusing and I noticed in my resin out line, half of it was filled with resin. The time I made a decent part, I barely had any resin in the line. I used the same 3 oz today as I did on that decent part.

I’m getting very discouraged and exhausted guys. I seem to take one step forward and two steps back.

Any help would be greatly appreciated. Thanks

Attempt #5