As a newbie to infusion I just this morning demolded my first infused part. What felt like a total disaster with the setup and the infusion last night actually provided some really good results.

The last mile to me would be to get rid of the small pin holes that I assume is trapped air. The gelcoat (vinylester) performed well and the cloth took the form very well. I think Id need to reposition and split the infusion point to infuse in both directions along the side of the part utilising a t-piece from the middle to the outer edges.

INITIAL SETUP

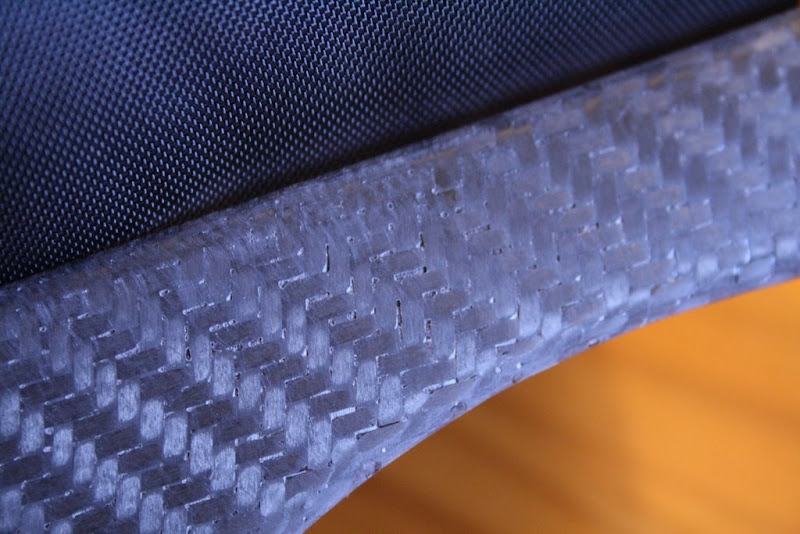

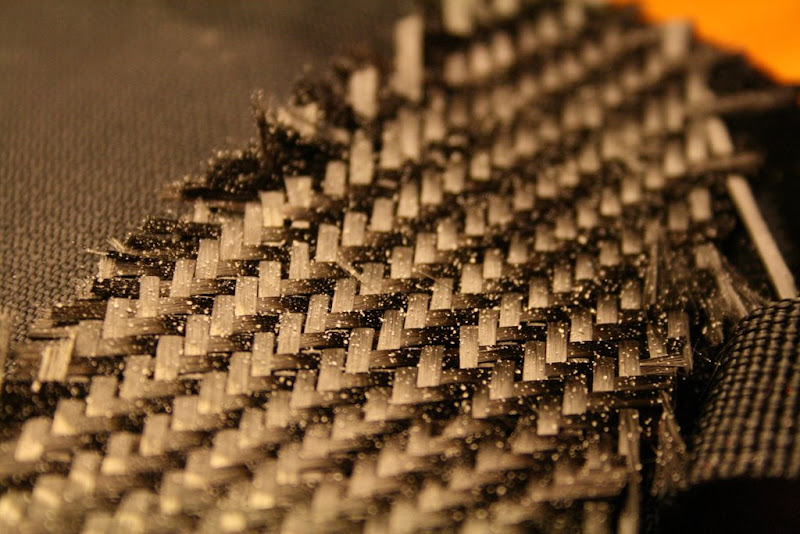

COMPLETED PRODUCT - LOOKS OK BUT AS SOON AS ITS LOOKED AT CLOSELY

INFUSION EDGE - SEEM TO HAVE LESS PINHOLES

PINHOLES - ANOTHER ANGLE

The epoxy flowed through the remainder of the system very very slow to the point that I got really concerned about the 30min pot life of the epoxy that was going to catch up. It ended up flowing through though.

Im now thinking of setting up the part to infuse with a strip of flow media all along the side of the part so that the epoxy could at least start infusing from the one long edge moving slowly across the width of the part.

Any ideas of how to get rid of these tiny pinholes would be of great help.

Sort of a working holiday …

Sort of a working holiday …