Hi! Im new here. Im playin round with a bit of carbon fibre and kevlar and have started making a few parts for our race cars (guards, boot lids, air ducts etc). Im normally sifting around racingcomposites.net and now ive found another fantastic site here!

We are looking to cut the roof out of our circuit car (Nissan Skyline GTR) and replace it with a carbon fibre skin. Our reason for this is to try and lower the centre of gravity of the car ever so slightly, and getting rid of weight in the roof is the best way.

We plan to wax the top of the roof, then do a carbon fibre overlay. Then release the overlay and cut it to shape.

Then we’ll either;

-use some type of foam or something (?) and resin it on the underside of the carbon fibre skin, followed by another layer on the underside, effectively leaving us with carbon/foam/carbon product

or

-lay another layer of carbon on the underside of the carbon skin to stregnthin it

pros and cons of each?

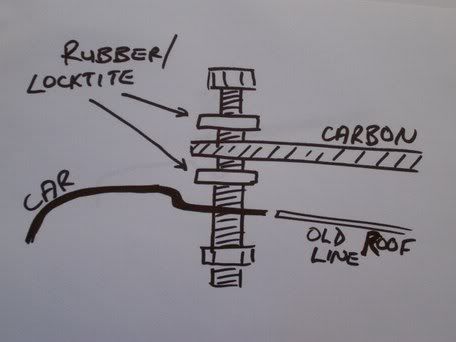

Then attach it as in the pic below, with both foam and locktite… (Its ART!! :):))

good ideas/bad ideas?

Let us know people!!!

thanks,

Adam