After using hand layup for a series of sandwich core CF parts, I’ve decided to learn the infusion process and I’m looking for some pointers.

For the first set of experiments, I kept it simple…

Part 1 from bottom to top:

[ul]

[li]flat glass plate (mold)[/li][li]PVA/wax[/li][li]3 layers, 6K 2x2 Twill 11.0oz/sq. yrd[/li][li]Nylon peel ply (1-2" larger than CF cloth)[/li][li]Perforated release film (same size as CF cloth)[/li][li]Flow media[/li][li]Vacuum bagging film[/li][/ul]

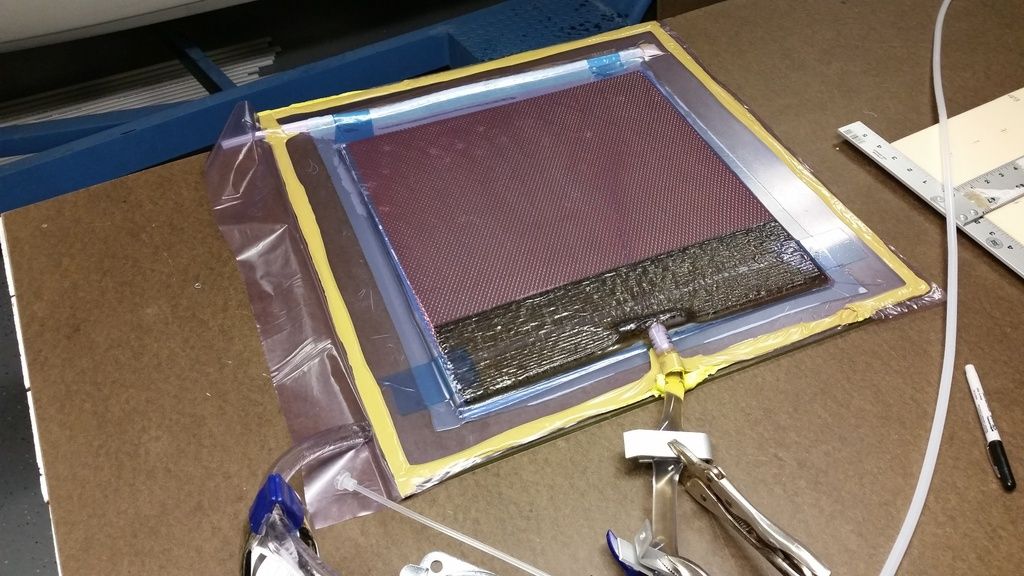

I used a degassed, <900cps epoxy (leftover from hand lay ups), MTI Hose on 3 sides of the plate and pulled <20mbar vacuum. The part came out exactly as expected with near perfect mold side cosmetics. SUCCESS!

Part 2 now includes Divinycell core and a second 3 ply stack. I also reduced the amount of MTI Hose by 1/3 and only used it on the side opposite the inlet line.

Bottom to top of Part 2:

[ul]

[li]flat glass plate (mold)[/li][li]PVA/wax[/li][li]3 layers, 6K 2x2 Twill 11.0oz/sq. yrd[/li][li]1/4" Divinycell (perforated with 1/16" drill every 2" in a grid and scored at perforations) [/li][li]3 layers, 6K 2x2 Twill 11.0oz/sq. yrd[/li][li]Nylon peel ply (1-2" larger than CF cloth)[/li][li]Perforated release film (same size as CF cloth)[/li][li]Flow media[/li][li]Vacuum bagging film[/li][/ul]

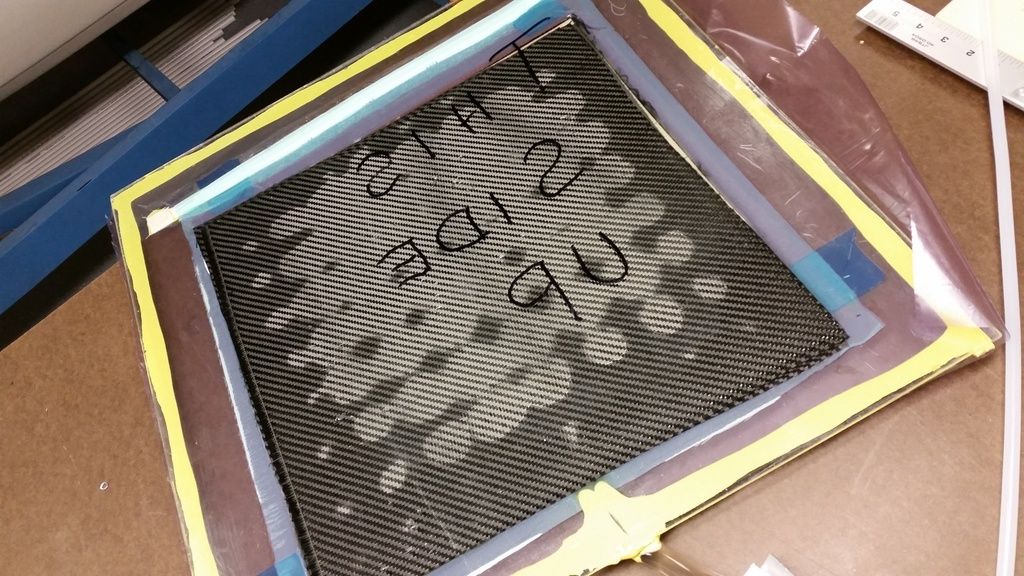

This time degassed <900cps epoxy, <20mbar vacuum, added a length of Enka channel. The top wet out nicely but the bottom was dry at each of the “islands” between the grids.

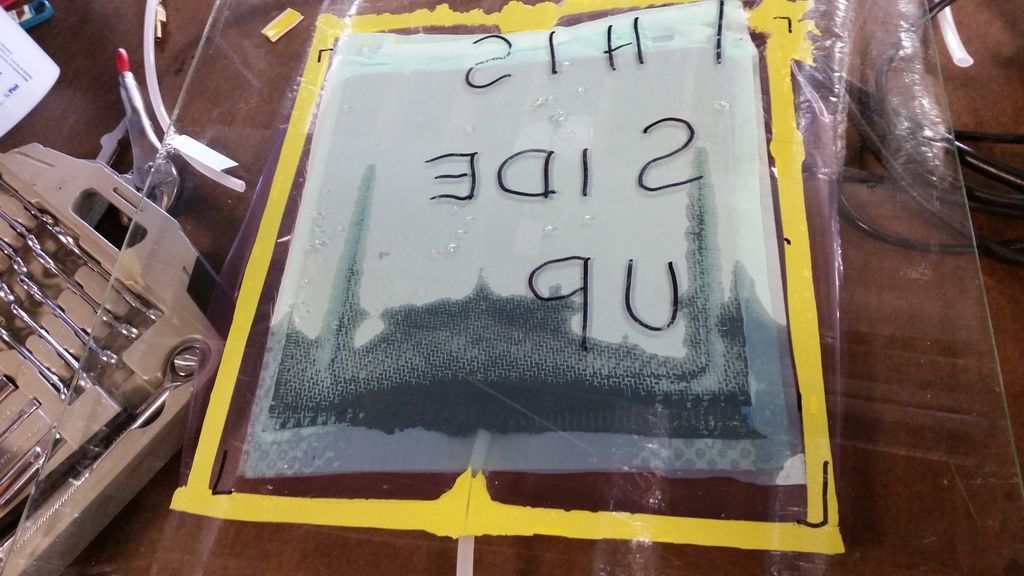

Part 3 now uses <600cps resin, a beveled core edge and I added a layer of peel ply between the glass and the lower stack. Same MTI Hose setup opposite the inlet line.

Bottom to top of Part 3:

[ul]

[li]flat glass plate (mold)[/li][li]PVA/wax[/li][li]Nylon peel ply (1-2" larger than CF cloth)[/li][li]3 layers, 6K 2x2 Twill 11.0oz/sq. yrd[/li][li]1/4" Divinycell (perforated with 1/16" drill every 2" in a grid and scored at perforations) [/li][li]3 layers, 6K 2x2 Twill 11.0oz/sq. yrd[/li][li]Nylon peel ply (1-2" larger than CF cloth)[/li][li]Perforated release film (same size as CF cloth)[/li][li]Flow media[/li][li]Vacuum bagging film[/li][/ul]

This time the epoxy penetrated further towards the MTI Hose, but was not completely wet out, similar to part #2 between the grid scores (islands).

Not knowing if it was the lower viscosity OR the addition of peelply, I tried a 4th experiment. Same stack as 3, but I removed the flow media. It infused about 20% and STOPPED.

What do you see I am doing incorrectly AND/OR what do you recommend for the next step?

Even thinner epoxy? Flow media top & bottom? Finer grid scoring (1" vice 2")?