Hi all - lots of great info here and I am hoping to get past the next hurdle by understanding what I am doing wrong.

I am fairly new to the infusion process so I set up simple test parts with the following results as follows:

Test Plate 1 used <900cps degassed epoxy @ <20mbar vacuum (GDH 200-14). I used 1/2" I.D. inlet line on one side with MTI Hose on the 3 other sides of the plate :

[ul]

[li]Vacuum Bagging Film

[/li][li]Flow Media (same size as CF cloth)

[/li][li]Perforated Release Film

[/li][li]Nylon Peel Ply (1-2" larger than CF cloth)

[/li][li]3 layers, 6K 2x2 Twill, 11oz/sq.yrd Carbon Fiber

[/li][li]PVA/Wax

[/li][li]Glass Plate (Mould)

[/li][/ul]

SUCCESS! Part was completely wet out with perfect mold side cosmetic finish.

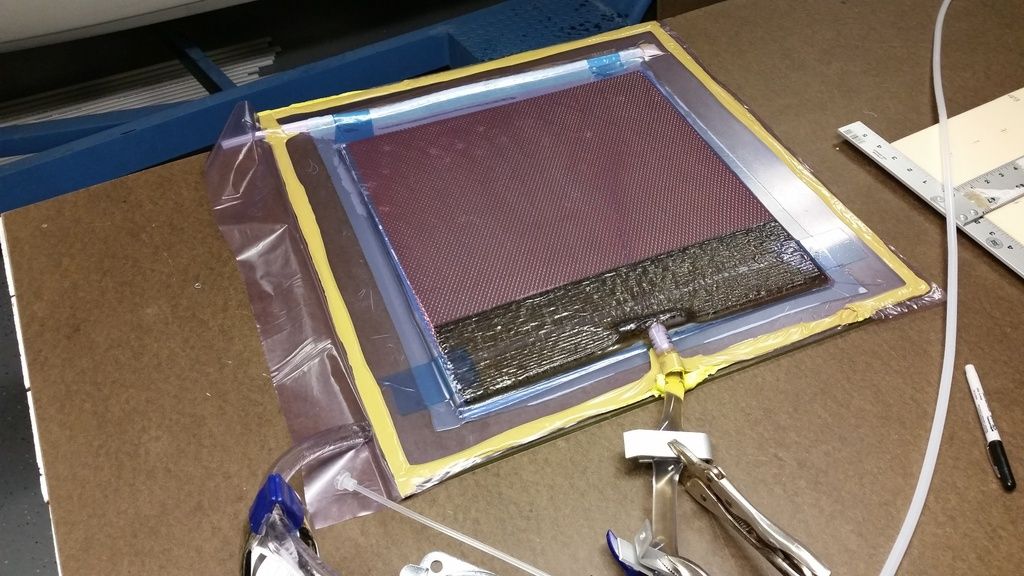

Test Plate 2 used <900cps degassed epoxy @ <20mbar vacuum (GDH 200-14). I used 3/8" I.D. inlet line on one side with MTI Hose on the opposite side of the plate (see pic) and introduced the 1/4" (6.35mm) thick core which I perforated with 1/16" (~1.5mm) holes every 2" (50mm) then scored lines across each set of holes with a razor blade resulting in a crisscross pattern:

[ul]

[li]Vacuum Bagging Film

[/li][li]Flow Media (same size as CF cloth)

[/li][li]Perforated Release Film

[/li][li]Nylon Peel Ply (1-2" larger than CF cloth)

[/li][li]3 layers, 6K 2x2 Twill, 11oz/sq.yrd Carbon Fiber

[/li][li]Perforated/scored 1/4" Divinycell core

[/li][li]3 layers, 6K 2x2 Twill, 11oz/sq.yrd Carbon Fiber

[/li][li]PVA/Wax

[/li][li]Glass Plate (Mould)

[/li][/ul]

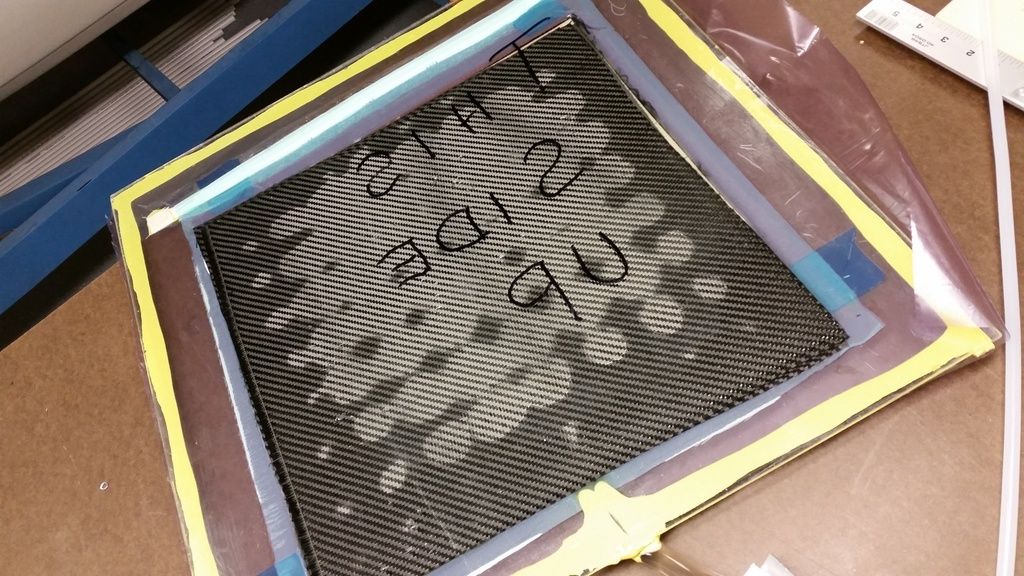

This is where the trouble started… The top looked great , but only part of the bottom stack wet out.

Test Part 3 was a repeat of 2, but now I used a thinner 600cps epoxy, beveled the core edges to 45 degrees and added a layer of peel ply between the CF cloth and glass mould expecting this to aid in the flow underneath the stack. The stack wet out better than previous try (with 900cps epoxy) but was still not completely wet…

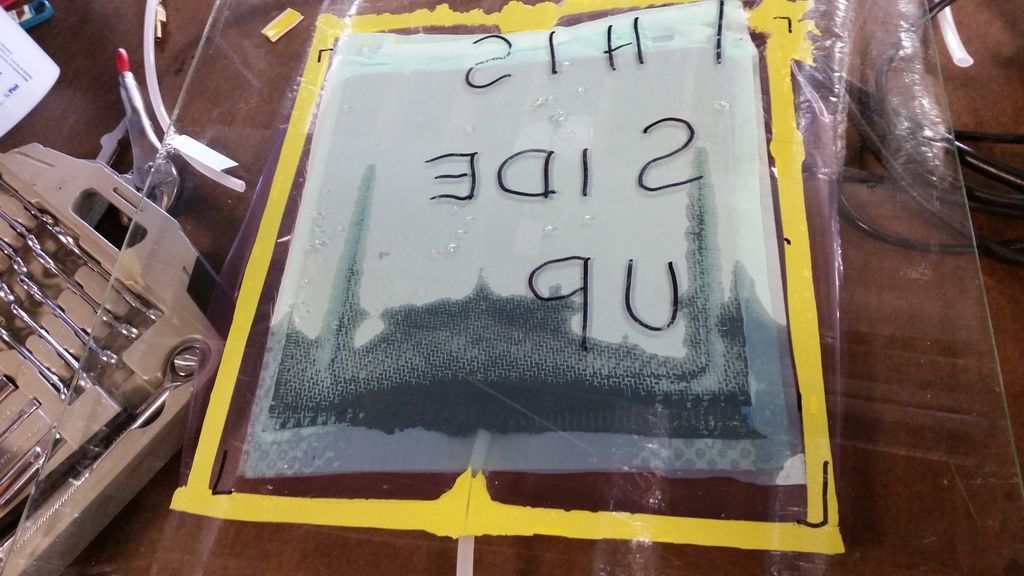

My last attempt was purely experimental. I removed the upper flow media and used ONLY peel ply to test flow. NOT A GOOD IDEA… The infusion “stuck” about 3 minutes in. The lack of flow is clear in the last picture.

I have thought about doing one of the following next, but I am open to any/all advice:

[ul]

[li]Score the core every 1 inch instead of 2?

[/li][li]Use flow media on both top and bottom of stack?

[/li][li]Use even thinner epoxy???

[/li][/ul]