So I’ve done some boat repairs and such before, but this is my first time actually making anything from composites. The part is an air intake plenum for dual Weber DCOE carburettors on a 4 cylinder engine. It’s a replica of a very rare cast aluminum piece from the 70’s. I could not access an original to make a mold from, so I measured and scaled some photos from the internet to get it as close as I could. I made the molds from MDF. There’s a mold for the top half and one for the bottom half and I’ll glue the two pieces together like a clam shell when they are done. I’m using US Composites epoxy with the fastest curing hardner and 3 layers of 10oz cloth. I started with a top half using only partall wax and it stuck in the mold. I was able to yank it out but it damaged the mold a little. So I then learned about PVA and tried that on a bottom half with great success. Now I’ve repaired the top mold and am ready to try it again. I also decided to try putting down a layer of epoxy in the mold and let it almost cure before laying up any glass since my first part had the glass coming through the surface. I don’t know if that’s the right way to do it, but I think it came out good. Feel free to add your suggestions or criticism, I’m very much a beginner at this. I’ll follow up when I get more parts made and installed on the car.

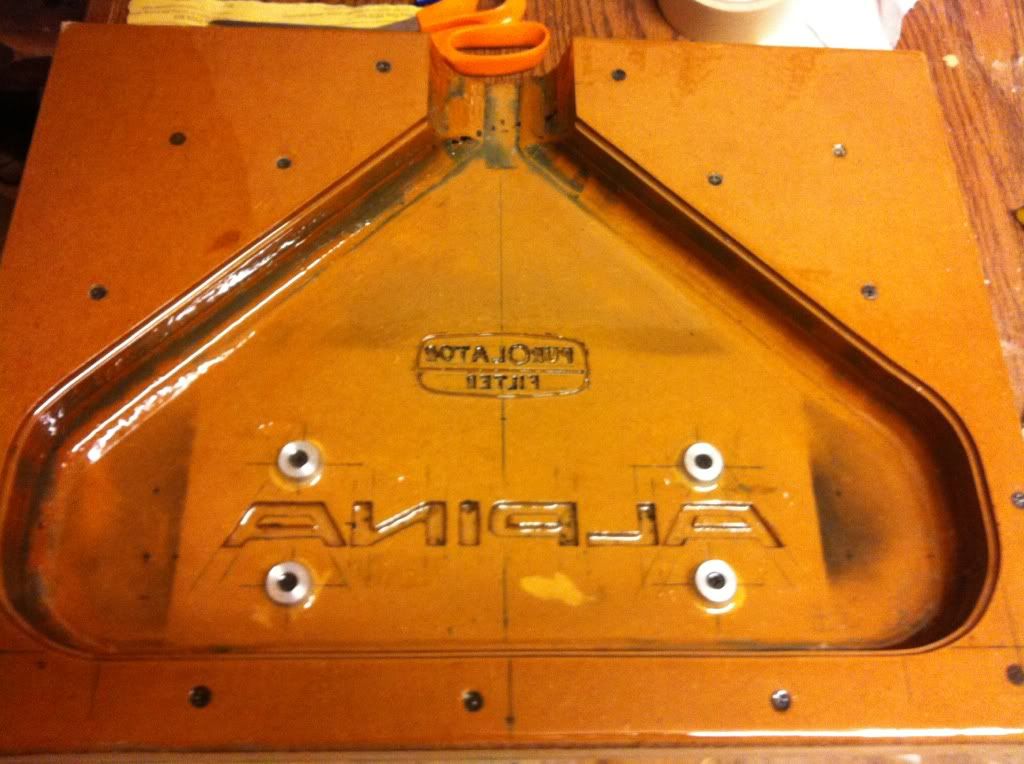

Sucess finally! A good bottom half (virtually the same without the letters):

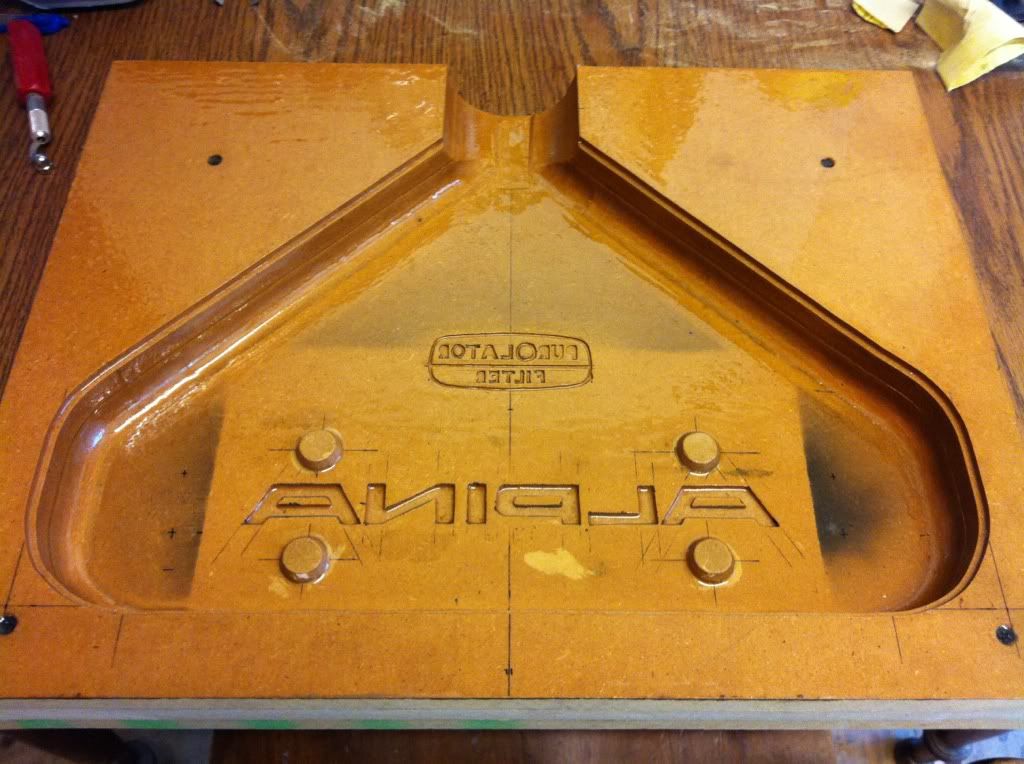

And the repaired top mold ready to go. Now using aluminum for the little risers since the MDF ones pulled apart: