I am about to start my final year at college for Manufacturing Engineering. It requires a fairly substantial project to graduate. It needs to have a research paper done on all the findings as well as state the improvements made.

I have a pretty much stock 2001 Camry and would like to make something for it. I am open to Ideas and any help would be appreciated. It does not have to be made for it as I am all ears. It is really getting close to the deadline where I need to solidify an idea and start working on it.

Fortunately, I have an abundance of resources available such as CNC Lathes, Milling machines, routers, and an autoclave for smaller composite Pre-preg parts along with vacuum components for larger pieces. Keep in mind I need to fund the project personally and would like to keep it relatively cheap. (Looking to spend around $1000)

For example one of my ideas is to completely remake the headlight assembly for my vehicle (2001 Camry) and have it built for a projector/HID setup.

Examples of previous years projects include carbon fiber hood, a completely redesigned guitar, carbon fiber roof carrier, carbon fiber strut bar, carbon fiber suitcase. I would like to preferably do something more unique and not something that was done in the previous year.

Thanks for any ideas you guys might toss at me, Don’t be shy please! I am really struggling with ideas right now.

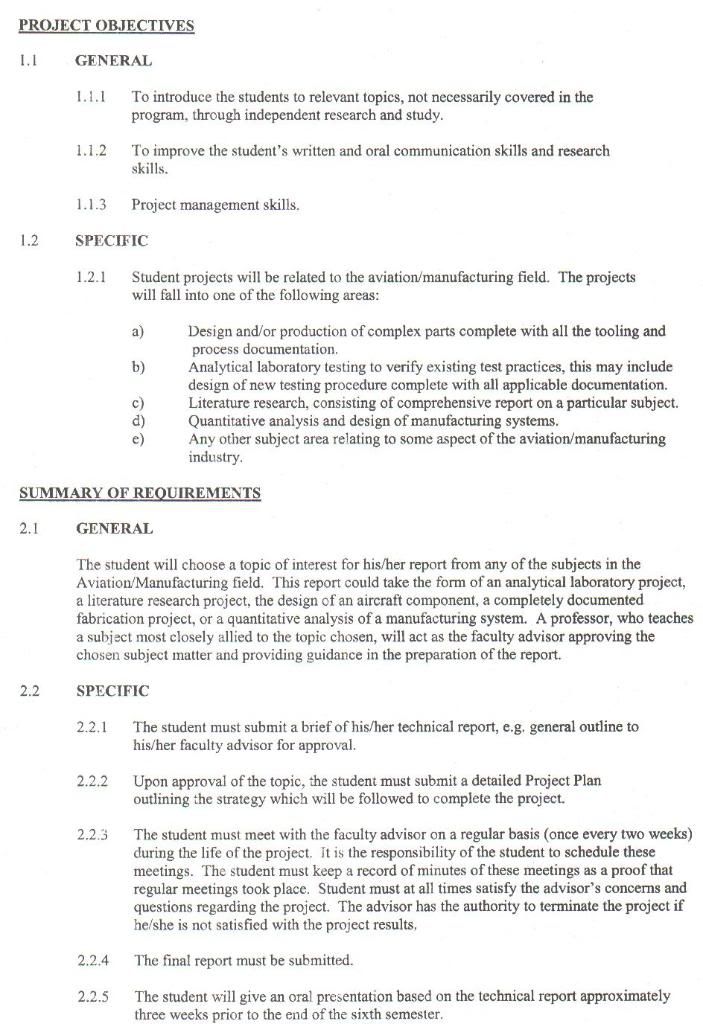

Attached is a copy of the requirements for the project, it allows for a great deal of ideas.

Previous ideas included a variation of the Sound Egg Chair, Motorized Kayak, Motorized surfboard. (Main reason for dismissing these ideas were due to cost and availability of jet-drive system and reviews on the sound egg chair)

(which is everyone here)

(which is everyone here)