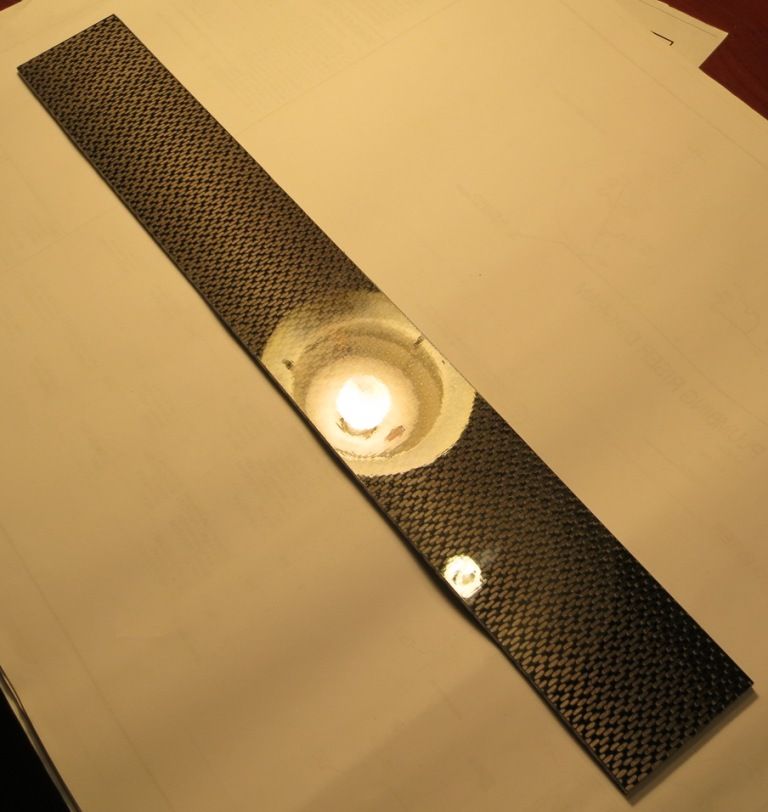

Did my first infusion, heck, this is my first composite part ever.  It came out flawless. It is just a test sample for more complex parts that I need to make for a large 28.5" (725mm) mirror diameter telescope project. I just need a starting point as I am new to making CF parts. So this sample serves as a data point for me.

It came out flawless. It is just a test sample for more complex parts that I need to make for a large 28.5" (725mm) mirror diameter telescope project. I just need a starting point as I am new to making CF parts. So this sample serves as a data point for me.

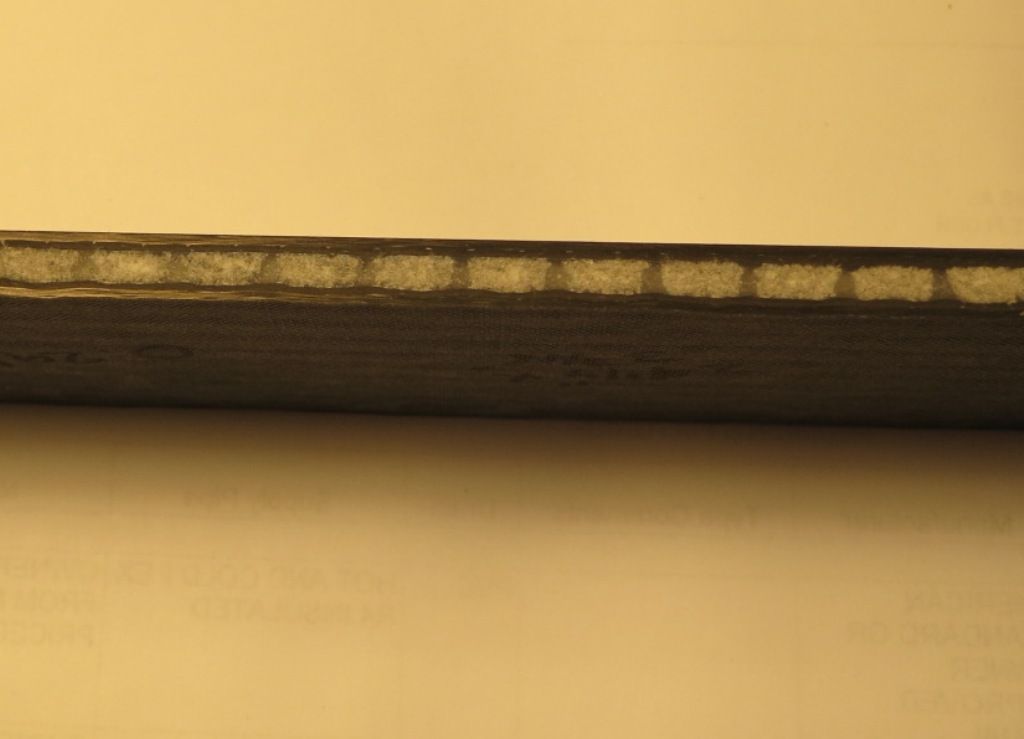

The layup I used is: (all CF)

204 gsm 4HS

3 layers 193 gsm uni (IM7)

810 gsm bi-axial

Soric 4mm

810 gsm bi-axial

3 layers 193 gsm uni (IM7)

204 gsm 4HS

Final thickness is 0.29" (7.36 mm)

Length is 24.25" (616 mm)

Width is 3.188" (81 mm)

Weight, with core, was 278 grams before resin.

Final weight is 383 grams after infusion.

That works out to be approx 46% resin content even with the 4mm soric core. Not too bad considering the Soric has a reputation as a resin sponge.

I have no print-thru on the face thus far. That may be due to the rather substantial amount of CF fabric on each face.

I did simple 3 point bending tests on this sample and find that in bending it is approx equivalent to aluminum of the same moment of inertia. Yet it is 2.5x lighter than that aluminum equivalent. I was hoping that it would be stiffer.

I need stiffer. In telescopes, the stiffness is the limiting consideration. Strength will never be the limiting factor. Stiffness is the ruling factor.

I guess the best way to do this will be by using thicker core material. What other core options do I have that work with infusion? I was thinking about trying Balsa, Divinycell H80, or Polyisocyanurate Foam, because they are available and on sale at Fiberglast. Would they work for infusion with some holes drilled and small channels cut in the faces? Any other suggestions would be welcome. Many of the parts to come are going to be complex and will need to have moulds created. Some parts I may need to use Soric for due to it’s ability to conform to a contour, others will be OK with a core that is just flat.

Any suggestions on changing my layup to gain stiffness? I understand uni will be the stiffest, and that is why I used 3 layers in the long axis, which is the axis that I was seeking to make the stiffest. I added the biaxial to give the sample some resistance to twisting, and the 4hs was just cosmetic on the surface. I can get intermediate modulus CF at a reasonable price, but going to a high modulus CF is just too expensive.

Thank you for your time and suggestions.

Still I try to get a little done when I can. My new 3d printer is almost built, just down to wiring and calibration. Hopefully soon cause I have some ideas that I need to be working on.

Still I try to get a little done when I can. My new 3d printer is almost built, just down to wiring and calibration. Hopefully soon cause I have some ideas that I need to be working on.