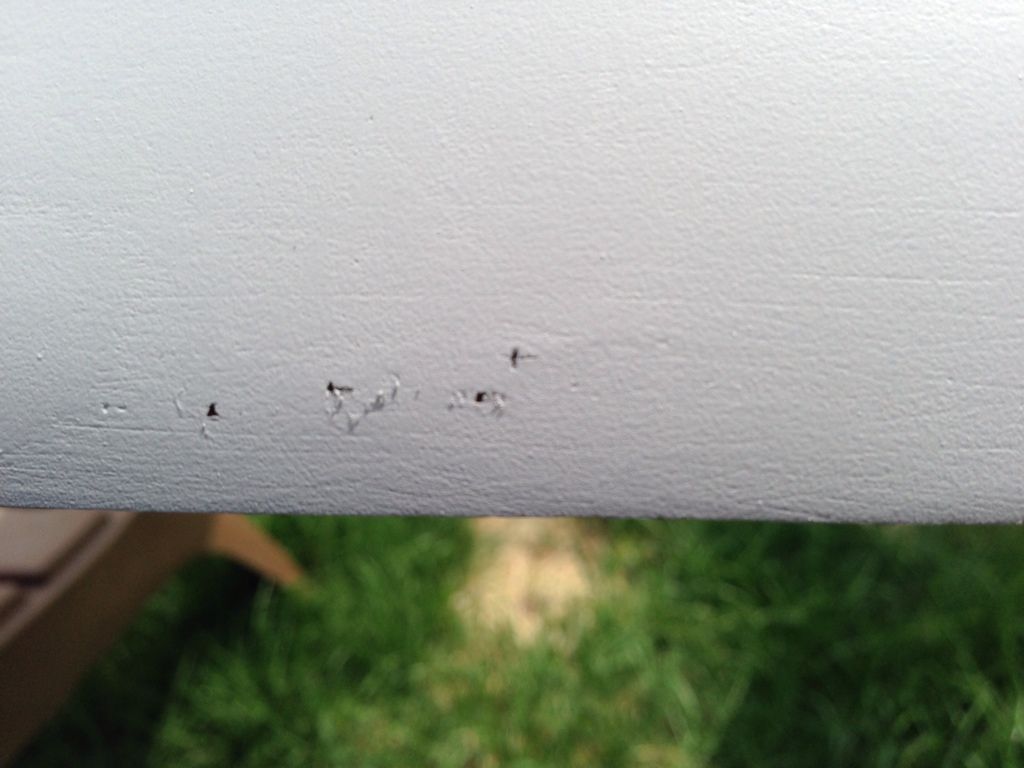

I am building a 7th generation civic and there is very little aftermarket support for this body style. I built a simple fiberglass splitter last year and it turned out nice, but I never really liked the gap between the splitter and the eBay chin spoiler right in the middle.

I wanted something unique, aggressive, and with a flat bottom to mount a splitter without a gap. What to do?

Build it:cool:

At first I wanted to go with something fairly simple and flat along the bottom. Like the lower edge of this Scion frs bumper…not a lot of angles and would be fairly easy to make:

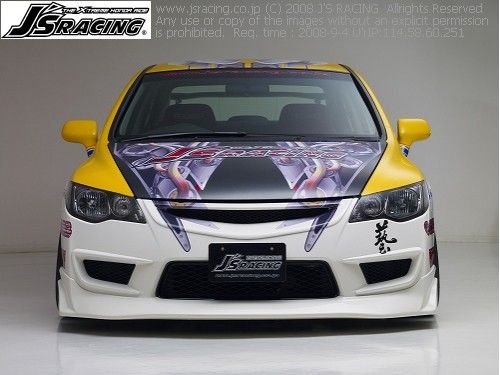

But I also like the style of the Js Racing chin spoiler for the 8th gen civic…

So I decided to build a “hybrid” version of both.

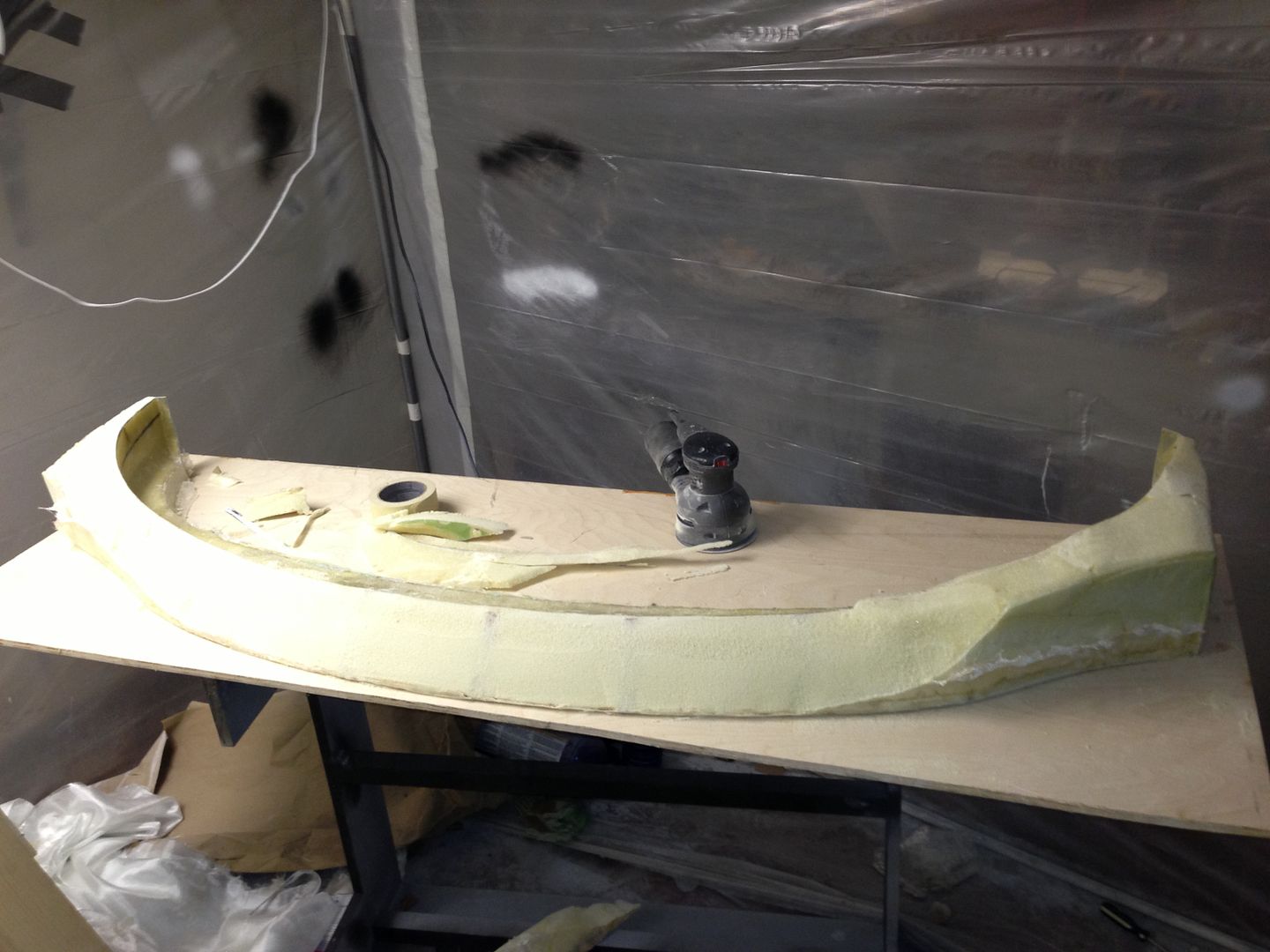

In order to get it perfectly flat with a nice symmetric curve across the front, I built a frame (my basement is so messy…I’m a little embarrassed to show these pics:o).