Hey guys,

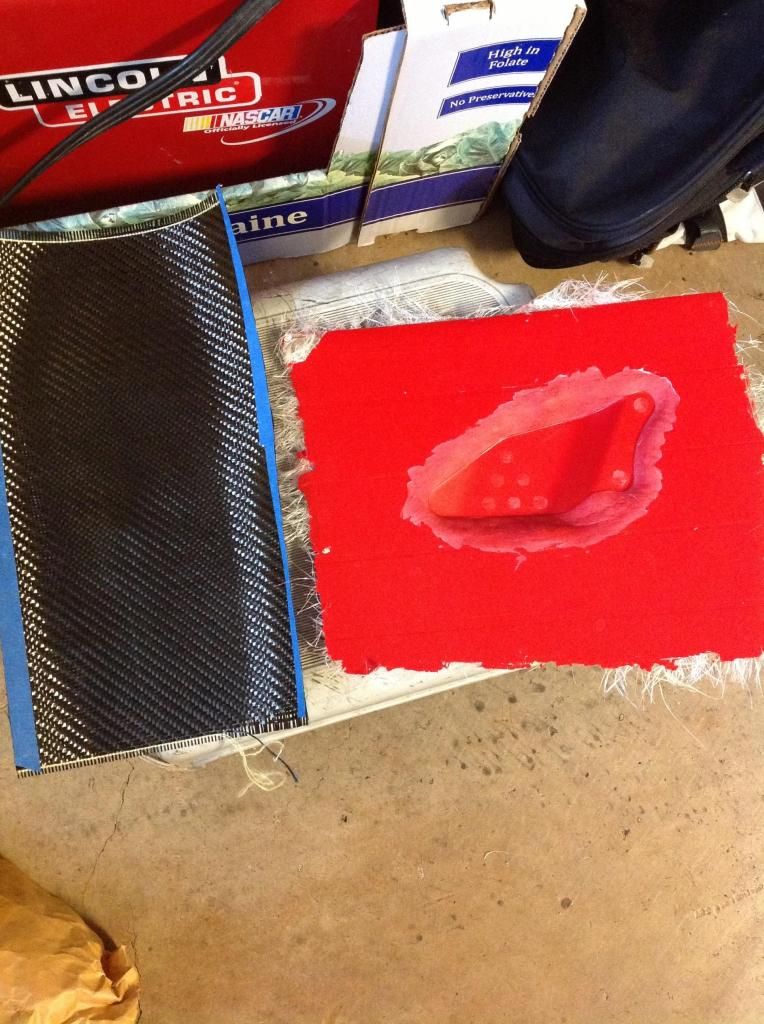

While waiting for my vacuum infusion supplies to come in, I was thinking of doing a hand layup of my mold using 5.7oz 2x2 twill carbon fiber. When I was pressing in the twill into the mold to see if it conforms nicely, I noticed that the weave was separating at certain points.

Is there any to prevent the twill from moving? I assume that it just doesn’t like to be pressed into a mold and is more for flatter objects? Or do I just suck?

thanks a bunch