Hi guys,

last month a customer order me 4 tables of 2.30m x 1m, 3 tables of 1.90m x 1m and 7 tables of 1m x 1m. The tables must be too strong and extremely very smooth surface without any waves on the top of it.

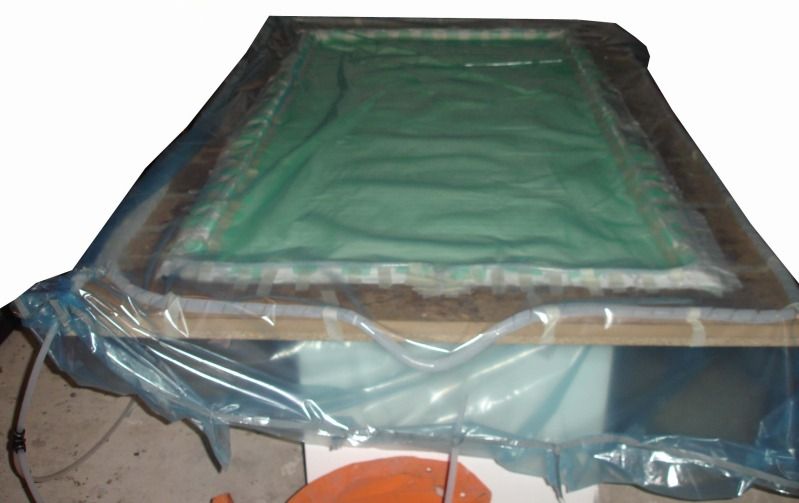

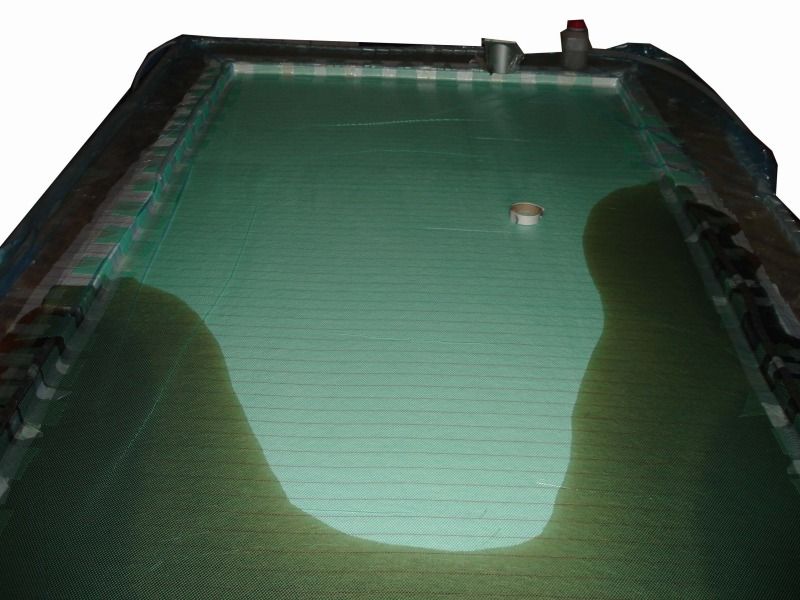

So the first think was the mold. I create the molds from Wood sandwich Laminates with nice curve borders inside.

All the panels was created with PLAIN carbon fiber plus poly plus foam. I use strong foam “60” and 1.50cm depth. All the proccedure is through infusion progress and using multiple input vacuum holes.

Tomorrow I will add some picture of all proccedure.