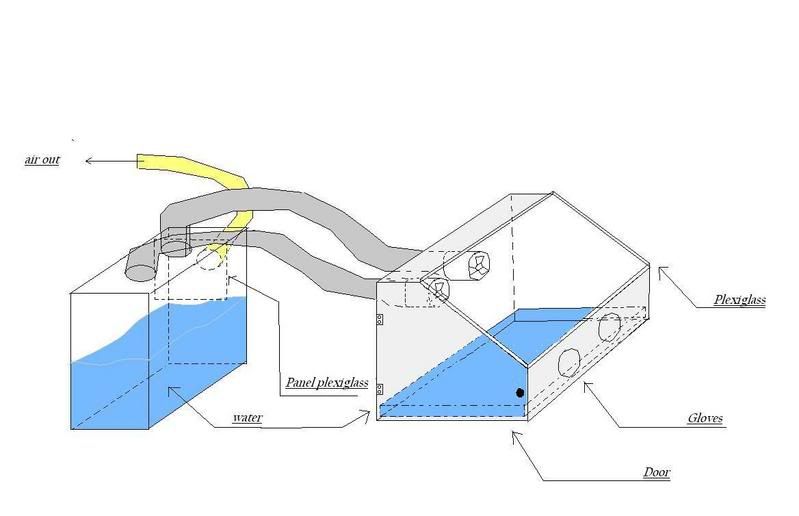

I decided to fix a box for my parts for more safety when I am cutting the Carbon moto panels. One box with at least 100cm x 100cm x 80cm with plexiglass and 2 turbo machines to take out the dust. All the dust is passing through one box with water and then get’s out. Here’s some photo:

Any ideas to make this machine much more practical? to filters, to box, anythink.

When I start this project i will put all the photos of the construction.

George

try it, george. a good book might be the solution to dust

try it, george. a good book might be the solution to dust