In this thread I’ll be showing the step by step of making a light weight, aero modified fiberglass 1 piece fiberglass front end from a stock steel front end. Many tricks and some mistakes that we learned from…:o

First, what was stock for this 1976 Mercury Capri MK2

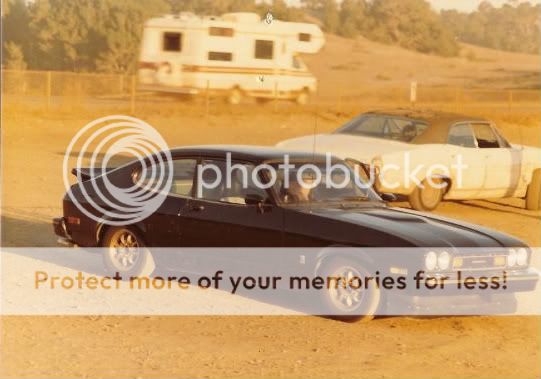

and the end result…

Stock OEM sheet metal already removed and getting welded together…

Stock OEM sheet metal already removed and getting welded together…