So I have been working of these hoods for a while now. They go on a Kawasaki X2

I have made about 8 now with varied levels of success from totsl disaster write off to nearly perfect, but never have I popped out a grade A part.

This is my first project using vaccuum and resin infusion.

I will try to be as detailed as I can in my process etc and maybe somebody can help me.

First I will illustrate the problems that are plaguing me.

These pictures were taken of a hood that was not worth trying to save because the pinholes (I think thats the term) is so bad. In these pictured it is coated in a heavy layer of body filler dust from sitting on a shelf in my body shop, but the dust actually helps show the problem. It seems as though the resin isnt fully wetting out the fabric.

I am using US composites thin Medium 3:1 epoxy.

Few coats of Meguairs mold wax (part sticking to the mold has never been an issue)

Layup is 5-6 layers of 5.7 oz 2x2 twill. I am using super 77 to help keep the fabric in place. Then a layer of peel ply, then green flow over the entire suface of the part (the times I didnt use green flow over the entire part I ended up with massive dry spots.)

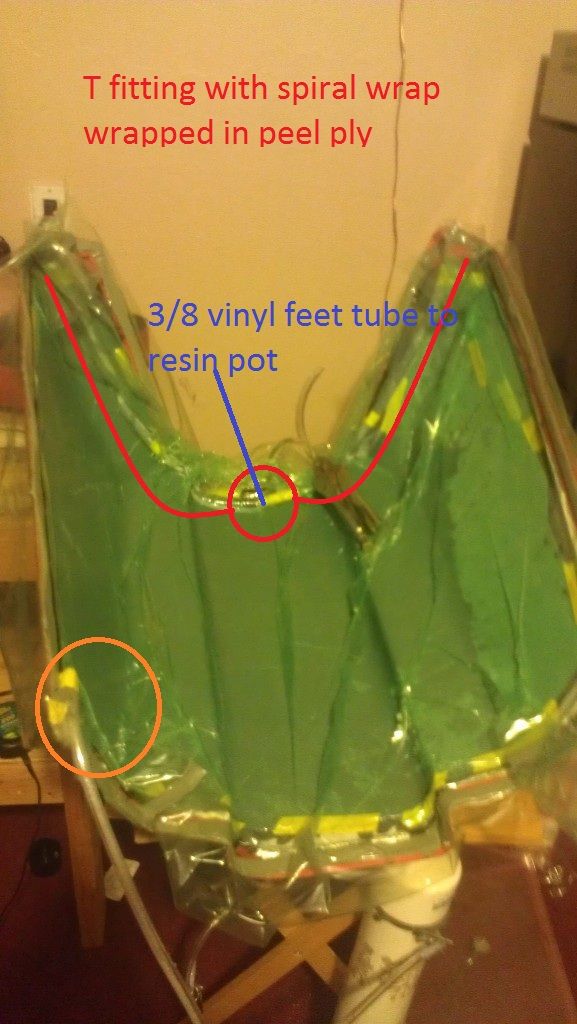

After the green flow im using a plastic “T” fitting with plastic spiral wrap wrapped in peel ply coming up the back of the mold at the widest points, and the “T” is then going into my feed pot. My vacuum out tube is at the front of the mold on one side. Then green stretchlon and gray bagging tape. Here is a crude depiction

After I finally figured out to take my time and be sure there are no air leaks, I usually get a nice even flow into the part. Occasionally, like with the part I did last night, for some unknown reason I had lots of very dry spots, as in the resin didnt even make it all the way to the first layer of carbon, but in that instance the layup was a combination of carbon fiber, fiberglass surfboard cloth, and fiberglass mat. Some of the part came out beautiful, but some was dry as a bone, with no logical explanation.

After I finally figured out to take my time and be sure there are no air leaks, I usually get a nice even flow into the part. Occasionally, like with the part I did last night, for some unknown reason I had lots of very dry spots, as in the resin didnt even make it all the way to the first layer of carbon, but in that instance the layup was a combination of carbon fiber, fiberglass surfboard cloth, and fiberglass mat. Some of the part came out beautiful, but some was dry as a bone, with no logical explanation.

I usually dont get dry spots in the full carbon layups if I take my time setting up the bagging process, but the pinholes have never stopped. It takes me an average of 8-10 hours in rework time to fix the pinholes, and the parts never look perfect even when Im finished. I was told maybe I was infusing too fast, so last time I kept a kink in the feed tube to really slow down the resin, and it helped, but didnt entirely fix the problem. I am also degassing my resin how using a large piece of clear acrylic glass over a metal pot with a vacuum tube into it, so there are no air bubbles in the resin. To get rid of the pinholes I have been brushing on resin then sanding it back. Then clearcoating using mipa 2k clear. I do not use any kind of clear coat or gelcoat in the mold face. I tried it once using 2k clear and it just didnt stick to the part at all, peeler right off like cling wrap

Please please help me. I really want to start producing some top notch stuff out of this mold I spend weeks making.

Also, I am very open to alternate, stronger (but still light) layup schedules. The hoods right now weigh an average of 6 pounds but I could get away with adding a few pounds to really beef them up. There is an inner baffle/air bladder that goes up one side which adds a lot of strength but I would ideally like to include some type of core structure in the hood, but the thought of trying to incorporate that into an infusion terrifies me. Every time I mess a hood up is costs me about $200+ and I cant keep losing money on this project but I refuse to give up.

Thanks so much