I’m pretty new around. Started experimenting with Carbon Fiber here a little while back. First ordered some 2x2 Twill 6k and for some reason chose the QUICKEST epoxy every. Resin Research Kwik Kick.

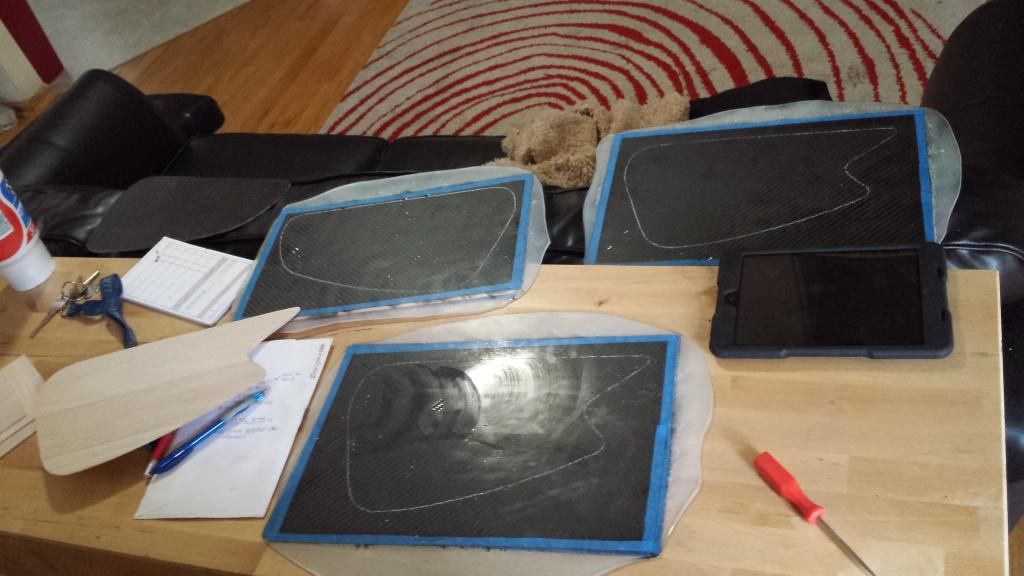

I went with 2 Layer CF, 1 layer 1/16in Balsa from local hobby shop, 2 layers CF. First mistake is I cut the balsa to size, but made the carbon fiber a huge rectangle. Ya you can’t tell where 1/16 of anything is 2 layers down. I compressed the wet layup between 2 big pieces of glass and used johnson wax unbuffed (ya I know). Here are some pics of results.

By the time you see this step. I’ve now used same sides CF and Balsa. BTW I only found 6in wide balsa, so I use superglue to attach using tips from model builders. Stuff is real easy to cut with razor.

So I needed to clear it and I wasn’t willing to use a standard clear. Bought some expensive 2k spray paint, which worked well enough, but cost is terrible.

And yes that’s speaker wire. In kitchen.

This is a clear that isn’t thick enough to cover my pin holes.

Sent to other end plates to be professionally cleared. Can’t wait to post up those pictures. My next project is a teaser here…