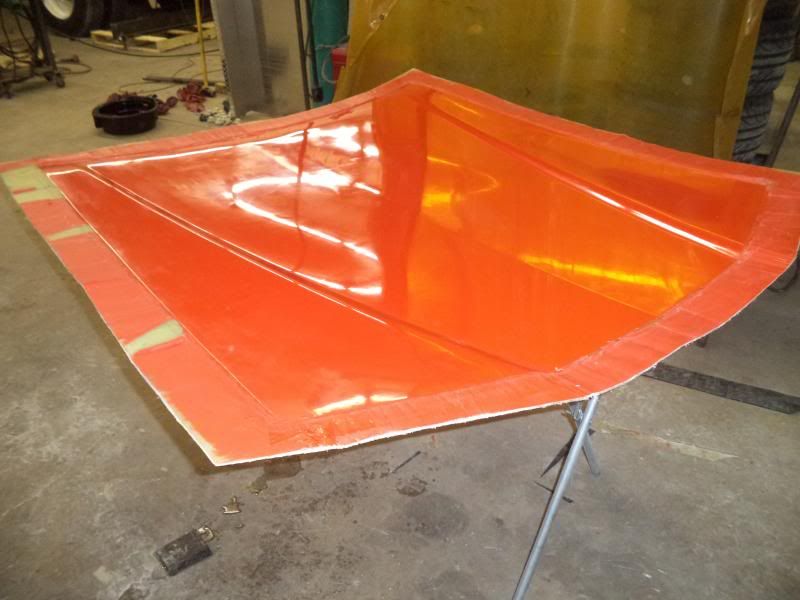

I used it on two molds(top and bottom of hood) and the topside of the hood came out decent, but seemed like it really didn’t want to release very easy(first mold I’ve ever made). I used 2 coats of wax on the hood, a coat of the Airtech Safelease, and 2 more coats of wax. There are a few minor imperfections that a little gelcoat would fix.

However, when I did the same for the underside mold, I ended up with a mess. Half the gelcoat stayed on the bottom side of the hood, it actually pulled the paint off the hood, and I pretty much destroyed the hood getting it out of the mold. The mold itself is repairable, and that’s what I’m planning to do, but its going to take a long time. I have more hoods like this one, but they are all currently on cars, and really don’t want to destroy another one.

I’m just wondering if other people have seen the same thing happen with this stuff?

What were the hoods painted with, and what mould system were you using? I’m gonna have a guess and say 1k paints and polyester/vinylester gelcoat?

Why you use wax with the release system? They’re two different types of systems. Heres the instructions from their site:

Use instructions:

> Thoroughly clean and dry mould surface.

> Shake well prior to application.

> Apply one light coat with a lint free cloth or with conventional spray paint equipment. Adjust the spray nozzle and air pressure to produce a light mist. Allow approximately 30 minutes drying time at room temperature.

> Apply a light buff with a lint free cloth to remove any excess.

> Mold is now ready for production.

Cycles:

Release All® Safelease 30 is capable of multiple release cycles with most resin systems.

The top hood was painted with Dupont Chromabase and ChromaClear. The bottom hood was painted with Dupont Imron single stage paint. It had been painted for roughly a month. I believe The Gelcoat was SeaHawk orange tooling gelcoat. I used 3:1 epoxy resin. I bought everything except the fiberglass and gelcoat from EliteMotoring on Ebay.

The reason for the wax was because I had been studying the How to Make a Carbon Fiber Hood on youtube from EasyComposites. I tried to find stuff that was as close to what they used in the video, but I guess I didn’t get everything right. Guessing that PVA needs to be used with the wax?

If you can’t get the same stuff that they are using then you need to do a test first. Too many combinations for them all to work the same way. I’d say the problem is the Safelease is a water based agent, water and wax do not mix.

Also, EC do not apply wax BEFORE the semi perm. Only after.