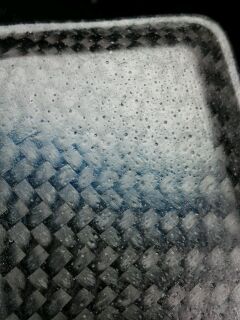

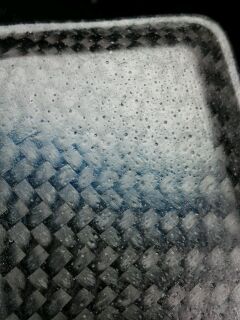

Hi everyone, so i have been working on this mold for a while now and have only pumped out 2 parts from it but both parts have this little problem with them. what causes it and how would i correct it?

Hi everyone, so i have been working on this mold for a while now and have only pumped out 2 parts from it but both parts have this little problem with them. what causes it and how would i correct it?

Pin holes…could be a bunch of different things causing it, did both parts come out the same in both cases you used this mould? Also, on other parts, not from the mould in question, has this happened before to you?

How was this made, did you do a wet lay-up/bag or was it infused?

How have the parts been made? We need more Details.

This pinholes you are seeing are from one of two reasons. Is the surface you are showing from the mold side? Could be the resin is not compatible with your release agent. You could also try degassing the resin before use.

I would make sure you degas your resin and then use MTI hose.

Mold is made with PE Tooling Gel, and the part was wet laid up and vacuum bagged with a silicone insert. the resin system is also PE with 5.7 2X2 twil. the mold is almost glass surface.

With air in the resin it would probably show some airpackets inside the resin too… They seem to be more of a surface problem of the mould. Possibly silicone or release product related. Did you use silicones directly on the mould? or sprayed in the same room?

Did you apply the fibre direct on the mould, or first applied a coat of resin? Applying the resin before the bubbles where mostly out could explain surface defects like this, but I think it is surface related.

I think it is a problem with the release agent. That are not classic pinholes caused from air. How long did you wait after aplying the release agent before laminating? Do you use a gel coat?

I thnk it could be the PVA too? No gel coat just PE resin. the two culprits i can think of is. i wetted out the fabric on some vacuum bag then applied it in the mold, or its the PVA. I waited a good 15-20 minutes before laminating. Should i used just mold relase wax next time?

I had the same outcome a while ago. Never happened before or after. The outside air was very moist and raining for days. Im not sure if the weather condition could have played a part of it?

Humidity can be a problem, 20min are quite short. Try to wait longer.

It’s def not what is normal pin holes in bagged cases, it’s from the PVA and release agent you used. Try it again but use a different release, the fail safe is paste wax. Other option is to cut out PVA and just use the release you did on this part.

Will do! thank everyone who posted here! you guys are awesome, its been said muliple times, but this forum kicks ass and we have some very smart/helpfull folks on here!