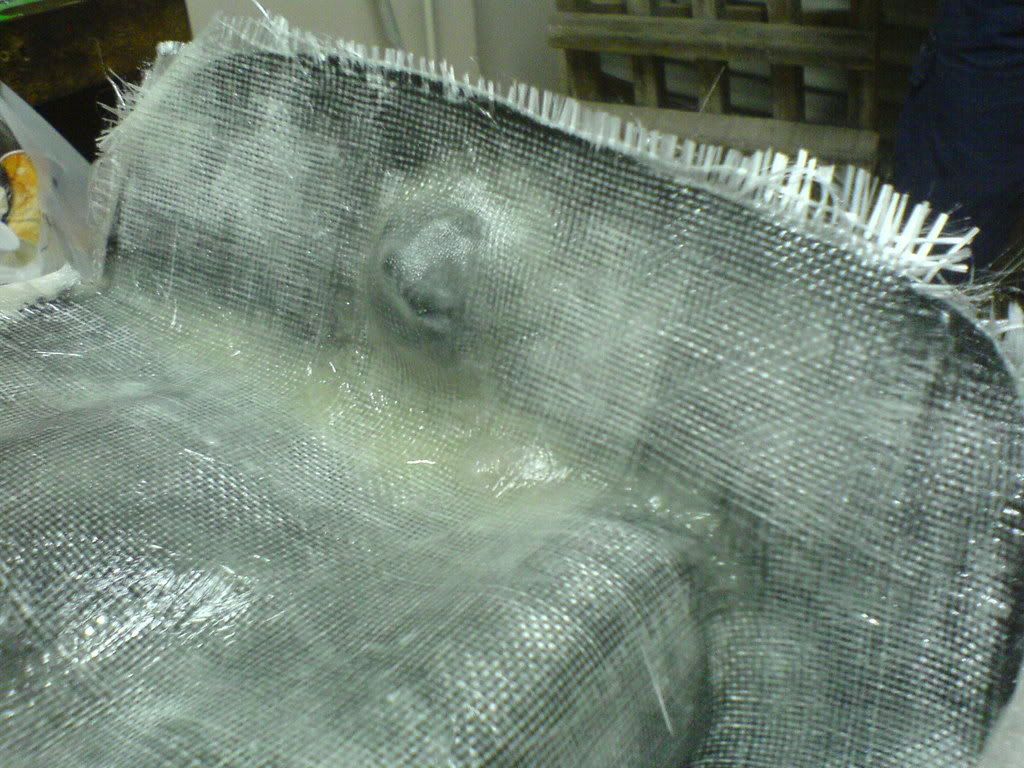

building up some volume on the center section

1st layer 100grm glass, 2nd layer 290grm twill glass, 3rd layer 380grm plain weave glass… combined with epoxy surface coat and epoxy resin, its gonna be damn strong! how much thickness you guys think i should go for? i don’t wanna waste too much materials for no reason… maybe another layer of 380grm?

oh i used some 3mm chopped glass fibers with epoxy for the corners and the tit-thingies on the flange…

took me 2 hours for just 1 layer of 380grm… i’m thinking of making some vertical reinforcements,to give more strength to the flanges connecting the 3 pieces together…

took me 2 hours for just 1 layer of 380grm… i’m thinking of making some vertical reinforcements,to give more strength to the flanges connecting the 3 pieces together…