Hey guys. First CF project i’m working on. Gonna be an intake plenum for my Nissan RB20. It will see at the most 20lbs of boost. I think i have everything worked out i just have a question about the first layer of glass which will attach directly to the aluminum base plate.

Here is the base plate i machined bolted to the lower intake runners.

Here is the original mold i made out of wood.

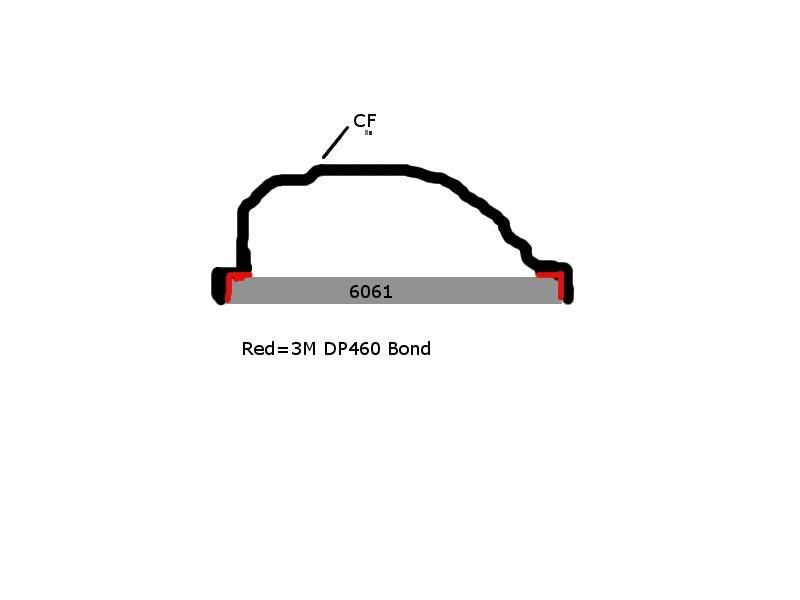

I was going to try and form some aluminum on this but that wasn’t working out too well. I will be making a new mold out of foam. The foam mold will be a little bit inset around the edges of the baseplate and i will wrap the glass/CF around the edge of the baseplate kind of like this [-----] ([) being the glass and (-) being the aluminum baseplate)so i can get a good bond to the aluminum. I hope that makes sense.

I will be using probably 2 layers of s-glass to bond to the aluminum to prevent galvanic corrosion. So my question is what is the best way to treat the aluminum so i can glass directly to it? From researching i found i need to etch it. Just wondering if anyone has any preferences for a certain product to use. I will be using West Systems epoxy and will be vacuum bagging it then use acetone to melt the foam mold.

… i thought the same exact thing. Utilize your aluminum plenum base, but drill and tap some holes around the perimeter… make a 100% carbon fiber plennum that bolts onto that aluminum base. If you make the plenum box have a horizontal mounting flange you could make your own gasket. Of course you will see a dozen or so bolt heads facing up all the way around the plenum but you will get a good tight seal. Also this way you could experiement with plenum geometry and size… having a two or three different plenums available for the same aluminum base.

… i thought the same exact thing. Utilize your aluminum plenum base, but drill and tap some holes around the perimeter… make a 100% carbon fiber plennum that bolts onto that aluminum base. If you make the plenum box have a horizontal mounting flange you could make your own gasket. Of course you will see a dozen or so bolt heads facing up all the way around the plenum but you will get a good tight seal. Also this way you could experiement with plenum geometry and size… having a two or three different plenums available for the same aluminum base.