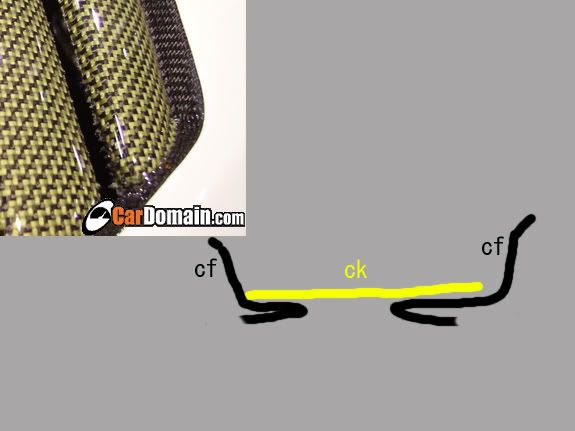

Do any of the pro’s know how to get the seen side of the fabric to “butt” together. I’ve seen guys butt together texalium and carbon with a perfectly straight line.

Any thoughts?

I too thought the outer edges were just tinted… you can see the yellow weave thru the tinted resin if you look closely. Just my opinion.